5 Axis CNC Machining Services

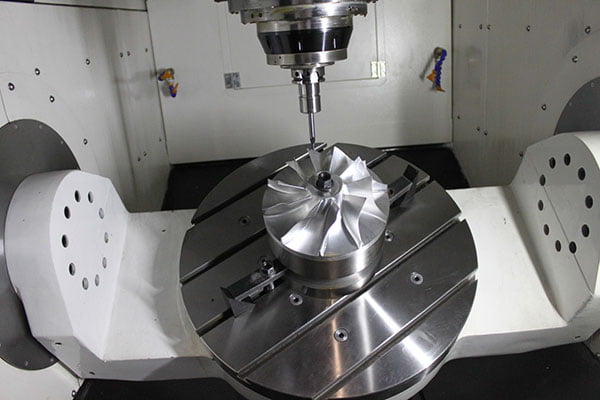

As an experienced and professional machine shop specialized in CNC manufacturing for many years, V1 Machining is capable of precision 5 axis CNC machining services and 5 axis milling. Whether you are in need of high-quality and precise metal or plastic components, we can provide 5 axis machining parts to worldwide clients for a variety of industries including automotive, medical, military, aerospace, mechanical, machine tool, high-tech, and more, with excellent machining and programming skills, as well as 5 axis CNC machining center. Our engineers and machinists can perform true 5 axis machining services work and produce five axis machining parts with ease. No matter how complex the CNC machining parts, each step will be executed with a rigorous attitude, to deliver exceptional 5 axis machining components that demonstrate the highest quality standards. Even though any problems during the process, we’ll keep running the job and make adjustments until all the issues are addressed.

What is CNC 5 Axis Machining?

The 3, 4, or 5 axis machining is defined related to the number of directions in which the cutting tool can move, this also determines the ability of a CNC machine to move a workpiece and a tool. 3-axis machining centers can move a component in X and Y directions and the tool moves up and down along Z-axis, while on the 5 axis machining center, the tool can move across the X, Y and Z linear axes as well as rotates on the A and B axes, which makes the cutter can approach the workpiece from any direction and any angle. 5 axis machining is different from 5-sided machining. Therefore, 5 axis CNC machining services allow infinite possibilities of the machined parts. Hook surface machining, unusual shape machining, hollow machining, punching, oblique cutting, and more special processes can be done with 5 axis CNC service.

Benefits of 5 Axis Machining Services

The 5 axis machining parts can be finished on a single 5 axis machine, which reduces fixture and setup preparation, saves a lot of time

Complex geometries can be processed with ease, high productivity and efficiency can be guaranteed at the same time

Excellent surface finishes can be achieved, improves the overall quality of 5 axis CNC parts

Expanded capabilities, higher accuracy, boosted throughput, and shortened lead time

Improved cutting conditions, maintain the optimal cutting, and reduce damage to the tool

Why Choose V1 5 Axis CNC Machining

High efficiency, saving cost

Our 5 axis vertical machining center equipped with multiple position tool changers, there is no need for setup on different machinery, allows 5 axis machining of complex parts with high efficiency, saving time and cost.

Strong Machining capabilities

5 axis CNC service at V1 Machining has strong capabilities to deliver precision machining products based on the demands and custom design given by clients, to reach or exceed your expectation.

Machining wide range of materials

We can machine precision CNC products with a 3/4/5 axis machining center from a host of materials, including aluminum, steel, copper, bronze, titanium, and more, to fill different specifications.

Complete quality control system

A complete process and quality control system in place to assess quality at every stage of our preparation, manufacturing, and inspection, to ensure the quality of 5 axis CNC machining components consistently meet the requirements.

Secondary processing services

A series of secondary processing and finishing services are offered for further processing, including 3/4 axis machining & milling, painting, sandblasting, anodizing, passivation, chrome plating, nickel plating, and more.

Fast turnaround & on-time delivery

Custom 5 axis milling parts with competitive prices, fast turnaround, improved productivity, and on-time delivery.

Products

.01

Mechanical Parts Machining's Capacity

For processing orders of mechanical part, all are produced and processed by “Mechanical Parts Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

72

Production equipments

49

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.02

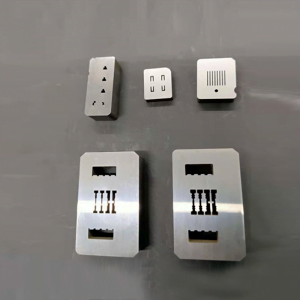

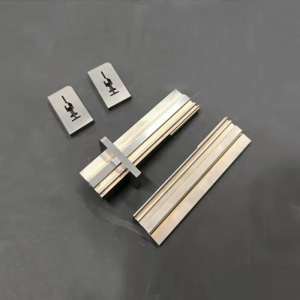

Precision Mold Parts Machining's Capacity

For processing orders of precision mold parts, all are produced and processed by “Precision Mould Parts Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

66

Production equipments

24

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

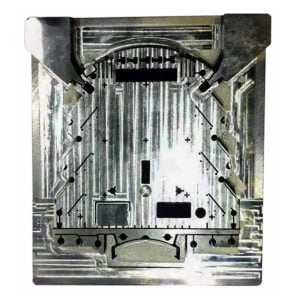

.03

Large Parts Machining's Capacity

For the processing and customized orders of Large parts, the “Large CNC Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

59

Production equipments

154

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

CNC Manufacturing Materials

Choose the right materials for your manufacturing needs from prototype to production

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries:

Custom CNC 5 Axis Machining Services

If you need any metal and plastic materials 5 Axis Machining and custom surface treatment services