5-axis machining advantages, disadvantages, applications, and service areas

With the rapid development of manufacturing technology, 5-axis machining is slowly being applied to various fields such as aerospace, electrical, medical, automotive, etc.

Machining Method

3-Axis

Use the tool to cut along the X, Y and Z axes from left to right and from front to back.

Features.

The tool moves along the entire cutting path and can maintain the same direction.

When machining complex parts, the technician may have to reposition the workpiece, which not only slows down the machining speed, but also increases the cost and eventually leads to defective finished products.

5-axis.

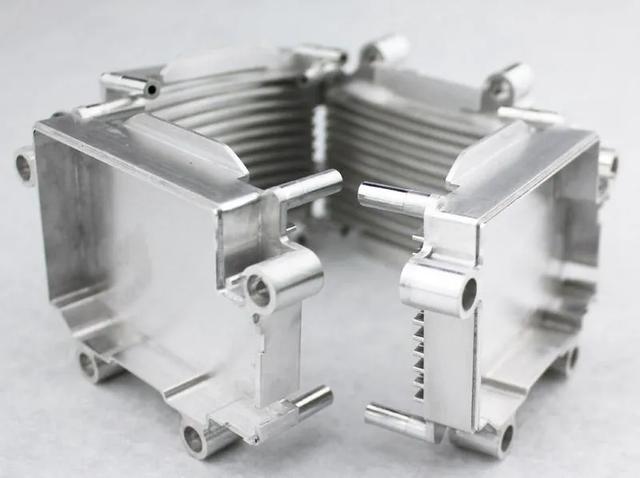

Linear interpolation through X, Y, Z, and two rotary axes can be used for a variety of machining methods, including 3-axis HSM, 5-axis drilling, 5-axis positioning, etc.

Features:

Optimized tool orientation and linear motion throughout the machining path.

Machining process

3-Axis.

Material remains fixed in the vise or machine tool

Rotary drill or tool is connected to the spindle and moves along the X, Y and Z axes

The material is shaved to create the final part

Suitable for the production of many geometrical and common parts.

5 axes.

Program code is entered on the machine and the tool rotates in the direction specified

Single set-up to finish the part

No need to manually reposition the workpiece during operation

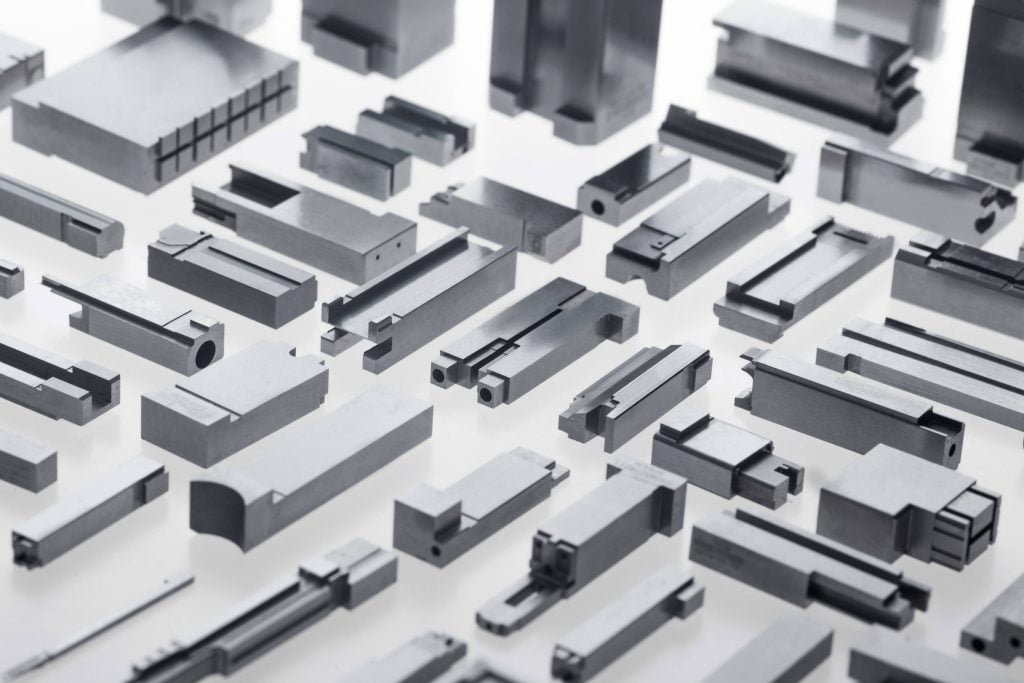

Ideal for the production of complex parts.

Notes on 5-axis machining

Notes on 5-axis machining

Compared with 3-axis machining, 5-axis machining has two additional axes, which makes its structure more complicated. For the same size machining machine, the 5-axis table is relatively small, so the size of the machined parts is limited. If you need to process large parts, then it is recommended to use a 3-axis machine.

Not suitable for rough machining

Compared with the 3-axis machine tool, the 5-axis machine structure is more complex and requires high precision, which is suitable for producing complex parts, such as aircraft parts, medical parts and so on. Roughing is the use of inserts to grind the material as deep as possible, and this kind of cutting process has a large resistance.

One side needs to be handled separately

5 axis machining does not mean that all sides can be machined. The side that is fixed as the bottom side needs to be set up as a separate program, and then the bottom side is machined before machining.

Expensive processing cost

Because the unit price of 5-axis machine is higher than 3-axis and 4-axis machine, and new CAM program has to be added to create NC data corresponding to the machine, so the unit price of parts processing is relatively more expensive.

Conclusion

When a Chinese 3-axis, 4-axis, 5-axis CNC machining part manufacturer is on a tight budget or only needs to produce simple parts, then choose a 3-axis machine.

If you want to produce more difficult jobs with complex geometries, then 5-axis machining is the best choice for Chinese 3-axis, 4-axis, and 5-axis CNC machining part manufacturers. By using 5-axis machining, your company will be able to produce larger volumes and higher precision parts.