What is swiss type Machining

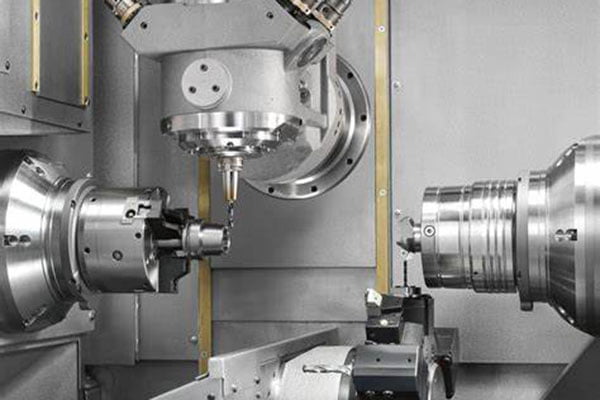

Swiss-type machining is a specialized machining used to manufacture small, complex parts with high precision. This type of machining is characterized by its small size, high accuracy, and ability to perform multiple machining operations in a single pass.

Key Characteristics of Swiss Type Machining:

Swiss-Type Lathe: Swiss Type Machining utilizes a specialized type of lathe called a Swiss-type lathe.

Small Size and High Precision: Swiss-type lathes are compact and capable of producing parts with high precision and accuracy.

Multiple Operations in a Single Setup: Swiss Type Machining allows multiple machining operations to be performed in a single setup, improving efficiency and reducing cost.

Guide Bushing: A guide bushing is used to maintain the position of the workpiece and prevent deformation, resulting in high precision and repeatability.

Sliding Main Spindle: The main spindle of Swiss-type lathe slides along the workpiece, which improves stability and accuracy.

Versatility: Swiss Type Machining can machine various materials, including stainless steel, titanium, and various alloys.

Cost-Effective: Swiss Type Machining is more efficient and cost-effective than conventional machining processes.

High-Quality Parts: The high precision and accuracy of Swiss Type Machining allow for producing high-quality parts with tight tolerances and intricate details.

swiss type machining's Applications

Aerospace and Aviation: Swiss Type Machining is commonly used to produce small, complex parts for the aerospace and aviation industries.

Medical Equipment Manufacturing: The precision and accuracy of Swiss Type Machining make it ideal for producing medical equipment such as orthopedic implants, surgical instruments, and dental components.

Electronics: Swiss Type Machining produces small, complex components for the electronics industry, such as connectors, switches, and circuit boards.

Automotive: Swiss Type Machining produces small, precision parts for the automotive industry, such as fuel injectors, fuel pumps, and valve components.

Watch and Jewelry Making: The precision and accuracy of Swiss Type Machining make it ideal for the production of small, intricate parts in the watch and jewelry industries.

Tool and Die Making: Swiss Type Machining produces small, complex tools and dies used in manufacturing processes.

Sporting Goods: Swiss Type Machining produces small, precision components for sporting goods such as golf clubs and bicycles.

Other Industries: Swiss Type Machining is used in various other industries, including food and beverage, optical, and power generation.

Swiss Type Machining Maintenance

Regular Maintenance: Regular maintenance is crucial to ensure the longevity and performance of Swiss Type Machining equipment.

Guide Bushing: Check and adjust the guide bushing to maintain the accuracy and repeatability of the machine.

Cutting Tools: Inspect cutting tools regularly to ensure they are in good condition and sharp, improving cutting performance and extending tool life.

Lubrication: Ensure all components are properly lubricated to reduce wear and tear and improve performance.

Cleanliness: Keep the machine and work area clean to prevent contamination and improve accuracy.

Electrical Systems: Inspect electrical systems to ensure they function properly and identify potential issues.

Software Updates: Regular software updates can improve performance and add new features to the machine.

Professional Maintenance: Consider hiring a professional service company to perform regular maintenance and repairs to ensure optimal performance.

Operating Procedures: Follow recommended procedures to ensure the machine's safe and efficient use.

Operator Training: Provide operator training to ensure the machine's safe and effective use and reduce the risk of damage or injury.

Conclusion

Swiss Type Machining is a specialized type of machining that utilizes a Swiss-type lathe to produce small, complex parts with high precision and accuracy. Using a guide bushing and sliding main spindle allows for multiple operations in a single setup, making Swiss Type Machining more efficient and cost-effective than conventional machining processes. The versatility and precision of Swiss Type Machining make it ideal for various industries, including aerospace, medical equipment, electronics, automotive, and watch and jewelry making. Regular maintenance is crucial to ensure optimal performance and longevity of the equipment. In conclusion, Swiss Type Machining is a valuable tool for producing high-quality, precision parts with tight tolerances and intricate details.