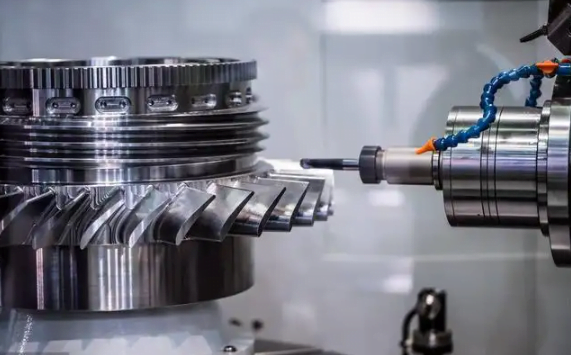

cnc machining CNC system as the name suggests, is a computer digital control, is the use of digital information to control the machine tool movement and machining process. It is a high-speed, reliable, multi-functional, intelligent, open structure of intelligent general-purpose CNC device. It is also an important indicator of a country's level of technological development and comprehensive national power as well as the modernization of information technology, especially in the national aviation, biological, medical and high-tech industries play an inestimable role, but also the level of national power. Therefore, the improvement of this technology is an important way to enhance the comprehensive national power and status of the country.

As a result, it is not only inefficient compared to traditional machining manufacturing, but there are often uncontrollable factors which make our work far below expectations. At the same time, the workload is high, and the requirements for our technicians will have certain periodicity and work limitations. Therefore, it is particularly important to use digital CNC machining technology, which is not only efficient, but also allows for simple repetition and subtle work that cannot be done with high precision and by the human eye.

CNC can be achieved simply, accurately, quickly and efficiently, and can be done perfectly with manual changes to the g-code and control programming language. From this point of view, it seems perfect to know that the cost and capital cost of CNC machining in our book is more expensive than traditional machining, but perfection should get better. In the future, we need to keep pursuing perfection and developing a perfect high-tech industry to better benefit us.