The automobile industry is an important pillar industry of China's national economy. It has a long industrial chain, a wide range of employment, and a strong driving force for consumption. It plays an important role in the development of the national economy. With the rapid development of the automobile industry.

High efficiency, high precision and high stability machining of complex key auto parts has become an effective measure to shorten product production cycle and improve enterprise efficiency and competitiveness.

CNC machining technology can realize rapid prototyping and manufacturing of complex automobile parts. At the same time, virtual manufacturing technology, flexible manufacturing technology and integrated manufacturing technology in NC technology have been widely used in modern automobile processing and manufacturing industry. The intelligent development of NC manufacturing technology in automobile parts production process will become a development trend of automobile manufacturing industry.

The Importance of CNC machining auto parts

With the rapid development of the automobile industry, efficient, high-precision and stable processing of complex key auto parts has become an effective measure to shorten product production cycle and improve enterprise efficiency and competitiveness. NC machining technology can easily realize rapid prototyping and manufacturing of complex automobile parts.

At the same time, virtual manufacturing technology, flexible manufacturing technology and integrated manufacturing technology in NC technology have been widely used in modern automobile processing and manufacturing industry. As far as manual manufacturing is concerned, numerical control technology has laid a foundation for realizing the standardization and standardization of automobile parts manufacturing and improving the production quality and actual equipment rate of domestic automobile parts.

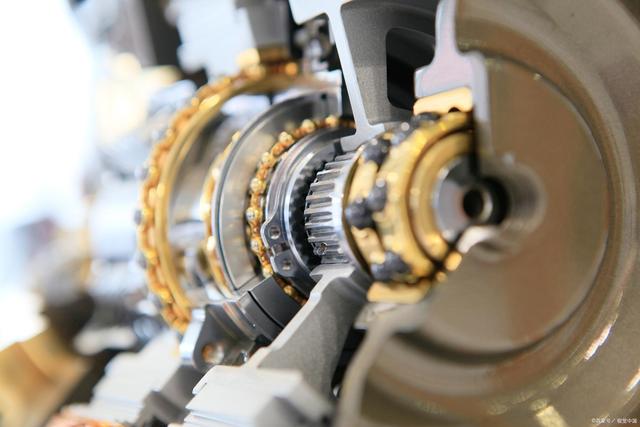

Types of CNC machining auto parts

Used in Automobile Parts NC Machining

CNC technology can provide a complete set of automation solutions for the manufacturing of key auto parts. Based on the industrial Internet and the monitoring and remote service of big data in the processing process, the processing data is received, followed by virtual processing and program code detection. Next, the self sensing, self-learning, adaptive and self optimizing functions of the CNC system are used to achieve high-quality processing of workpieces.

Then, industrial robots and online batch inspection methods of CNC machine tools are used to realize the extensive application of CNC machine tools in efficient flexible processing and batch manufacturing of key auto parts.

For the manufacturing of thin-walled housing parts in the automotive industry, such as engine housing, gearbox housing and other milling processes, some special post-processing programs should be loaded, such as the reduction of machining accuracy due to cutting vibration caused by low stiffness housing during the cutting process. Adaptive speed control and torque and torque monitoring modules for each axis of the machine tool should be loaded to automatically adjust the spindle speed to maintain the cutting stability of each axis torque, Improve processing quality and efficiency.

Prospects for the development of CNC machining auto parts

In the face of the demand for integrated intelligent production and manufacturing of high quality and high efficiency of complex parts with multiple degrees of freedom, the future CNC system will develop towards the direction of multiple degrees of freedom composite processing, and realize the multi process composite processing of turning, milling, drilling, etc. with multiple machining surfaces by one clamping.

In addition,CNC system needs more advanced trajectory planning strategy and motor control strategy to achieve high-speed and high-precision machining.