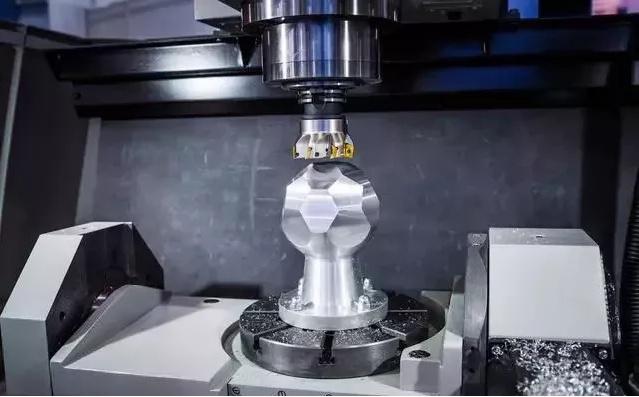

In the manufacturing process of aircraft CNC machine tool parts, many metal parts are needed, and the parts need to be machined before they are used, so that the size of the parts can meet the requirements of the design drawings and the assembly accuracy of the aircraft parts can be achieved.

The processing of parts mainly depends on CNC machining technology, through CNC machining technology to improve the accuracy of aircraft parts, so as to achieve mass production, it is clear that CNC machining technology in aircraft manufacturing plays a very important role.

Overview of CNC machining technology

In recent years, numerical control machining technology has been widely used in various manufacturing fields by virtue of its excellent performance. CNC machining technology in the application process mainly has the following characteristics, first, to achieve the improvement of accuracy, whether it is time error accuracy or processing quality accuracy, CNC machining technology can be greatly improved.

Second, improve the repeatability of processing quality, the application of numerical control processing technology can not only ensure the balance of processing parts quality, but also has an obvious role in parts processing quality.

After years of practice we can find that CNC machine tools can not only effectively improve the production and manufacturing capacity, processing quality, processing accuracy, effectively control the rate of waste and defective products, but also can effectively reduce the operation difficulty of machine operators, to achieve an operator operating multiple machine tools at the same time.

In addition, CNC machining technology can also effectively reduce the turnover between each process, facilitate design changes, effectively reduce the processing cycle.

With the increasing maturity of computer information technology and the improvement of the numerical control degree of manufacturing equipment, the application of numerical control machining technology in aircraft parts processing is deepening.

The importance of CNC machining technology in aircraft manufacturing

Numerical control machining technology is an important technical means to support aircraft manufacturing. It can cut and polish important parts of the aircraft, and obtain the accuracy and surface quality to meet the requirements, making the aircraft manufacturing process more convenient. The machining process in the manufacture of aircraft.

Can well be realized with the aid of numerical control processing technology, both to ensure the quality of machining parts, and improve the efficiency of the machining parts production, this is artificial far and, show a very powerful technical advantages, but also to avoid the uncertainty due to human error, greatly reduces the risk of airplane flight.

In recent years, with the emergence of aircraft accidents in an endless stream, the relevant departments and units have intensified the review of manufacturing technology, improved the quality awareness of technical workers in all links, and more strictly controlled the manufacturing process.

Under this big background, the nc machining technology is also to a large extent adjustment and upgrading, make it a better service for aircraft manufacturing, data processing technology show a softer, more accurate and efficient new characteristic, makes the automation in terms of technical level than in the past have greatly improved, also make a variety of aircraft parts with complex structure can realize batch production, And then make a better contribution to aircraft manufacturing.