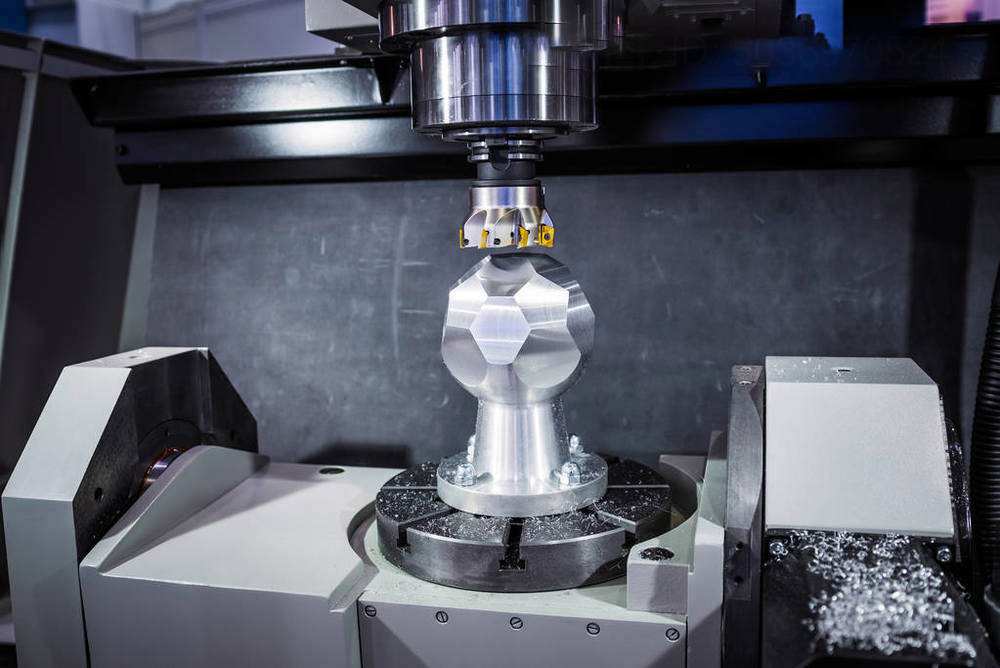

CNC metal parts processing - design and application of multi piece processing fixture.

With the progress of science and technology, the mechanical processing equipment has been continuously optimized and improved, its processing capacity and accuracy have been continuously improved, and the mechanical processing technology has also moved towards the direction of high efficiency and accuracy. The complicated process steps have been gradually optimized and reduced, the machining time […]

CNC metal parts processing - design and application of multi piece processing fixture. Read More »