How to make precision machining parts of medical equipment by CNC machining?

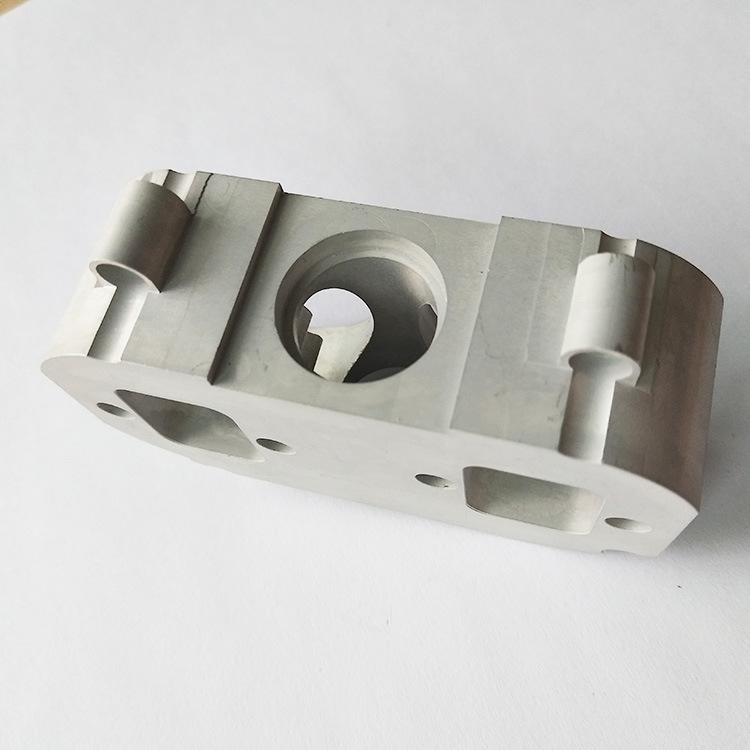

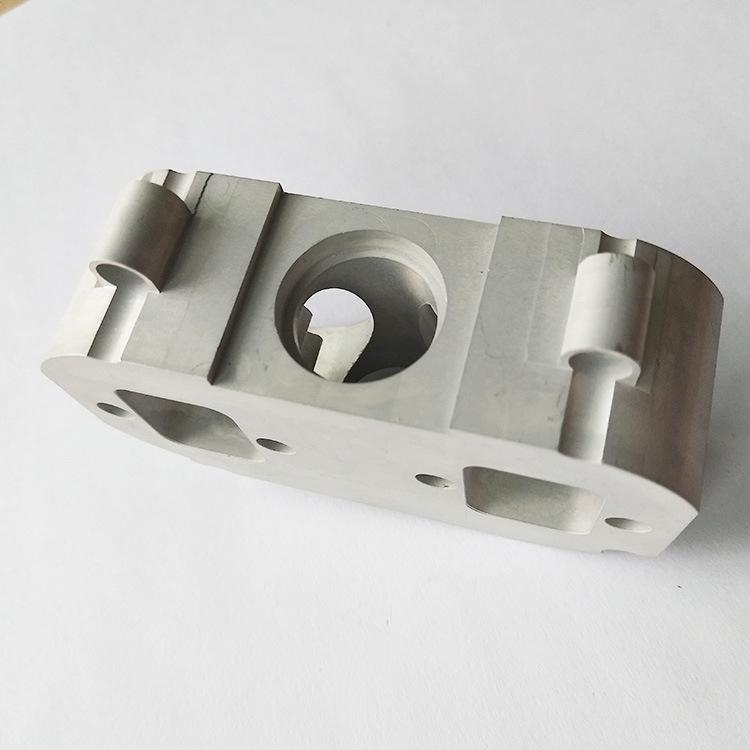

Items processed and manufactured by CNC include various surgical instruments used in medical operations, such as trocar (skin piercing device), bone drill and saw. When CNC is used to precision machined parts for medial devices, the parts are usually milled with 3-5 axes or turned with a movable tool CNC lathe. The most common types of machines used in the manufacturing […]

How to make precision machining parts of medical equipment by CNC machining? Read More »