The Essential Guide to Stainless Steel CNC Machining

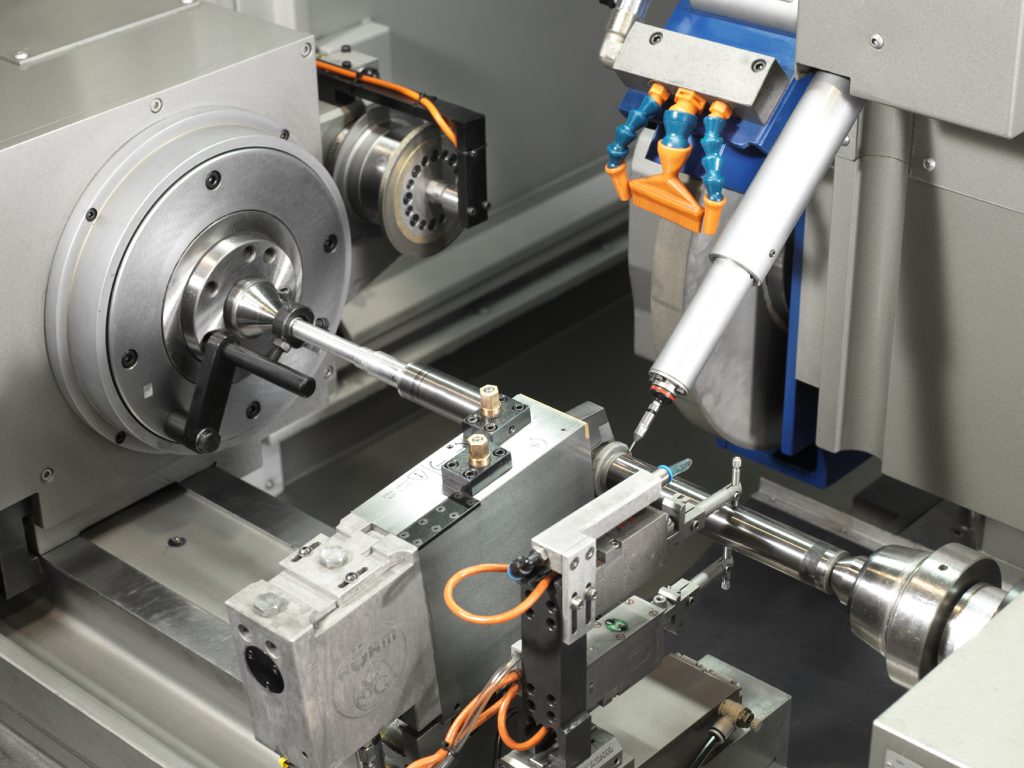

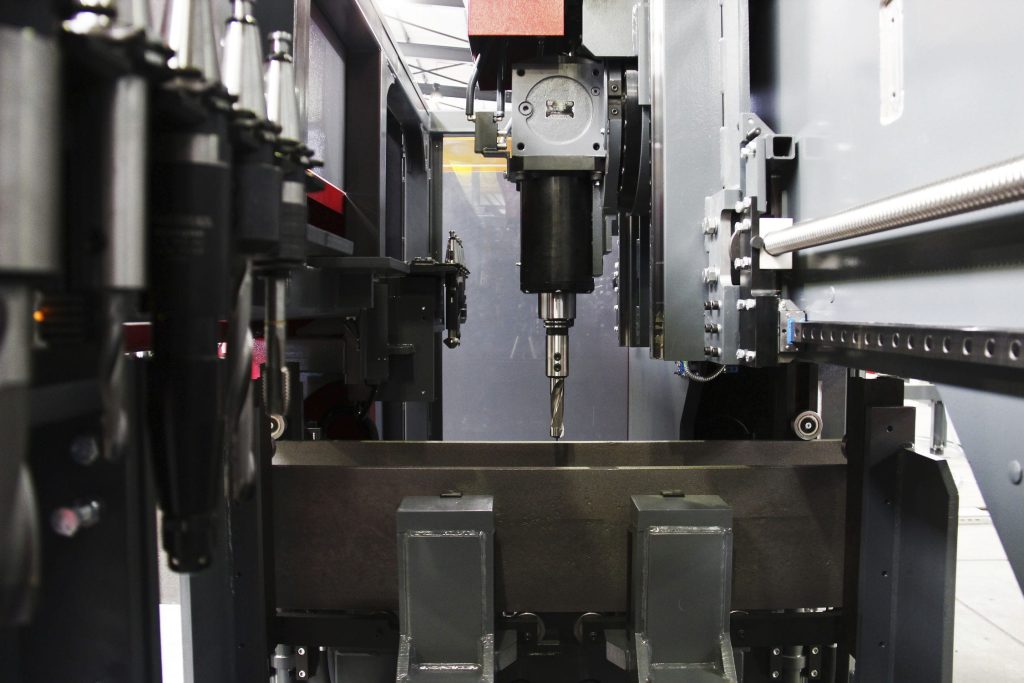

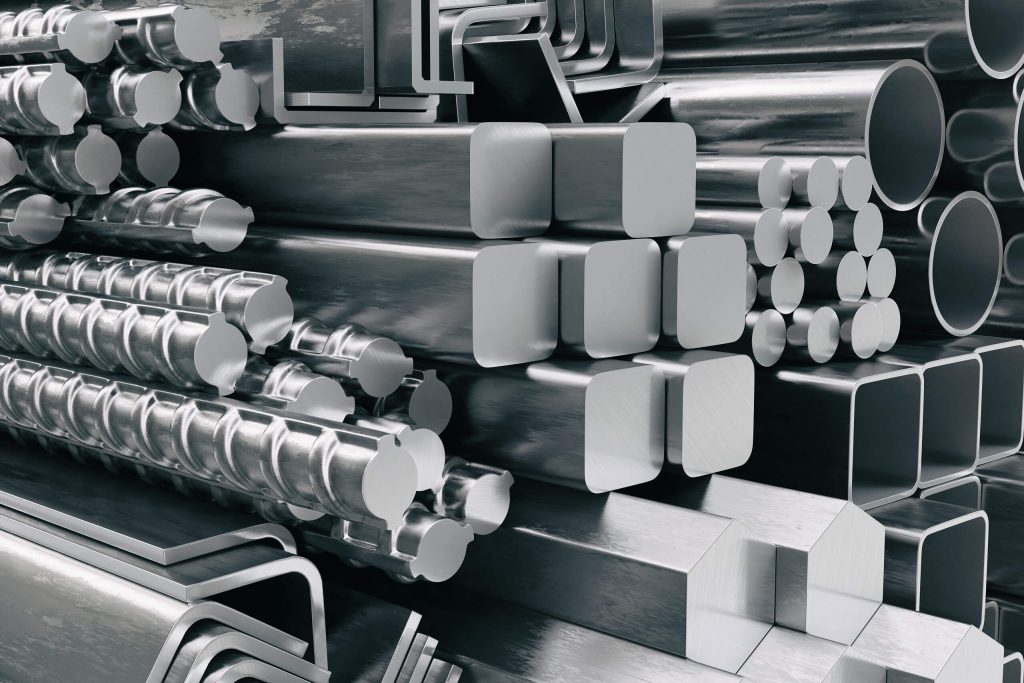

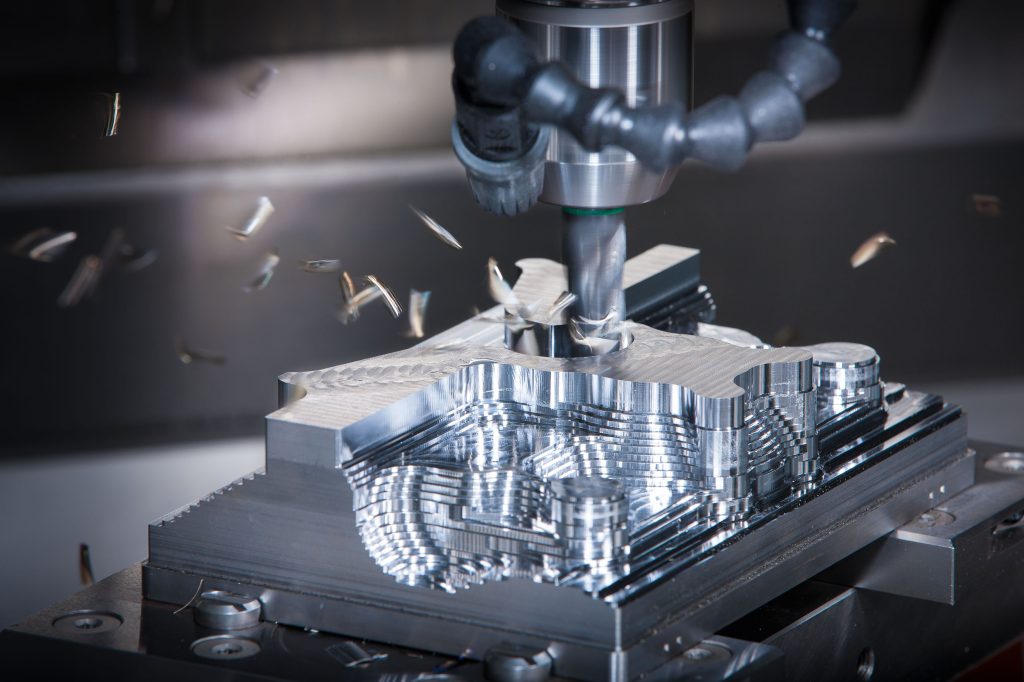

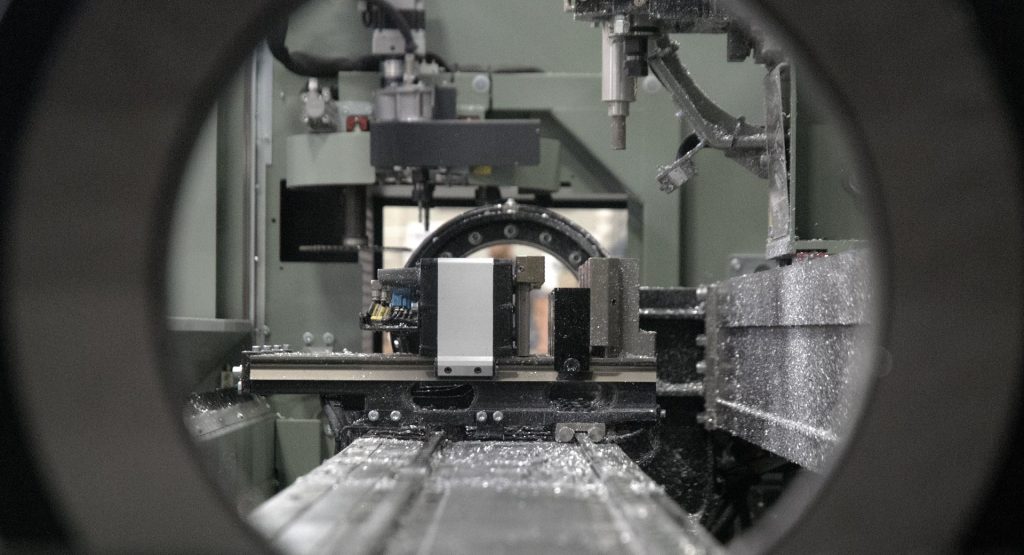

Stainless steel CNC machining is the process of using computer numerical control (CNC) to cut and shape stainless steel into a desired shape and size. Stainless steel is a popular material used in various industries due to its high strength, durability, and resistance to corrosion.

The Essential Guide to Stainless Steel CNC Machining Read More »