Methods to improve the efficiency of precision parts machining

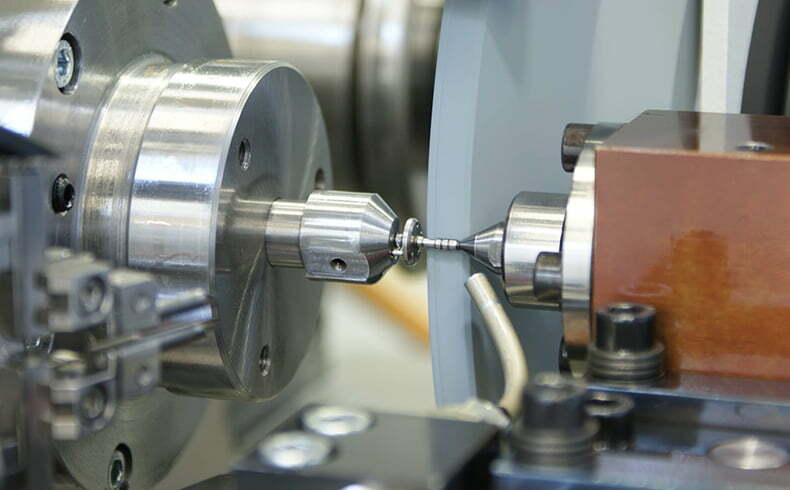

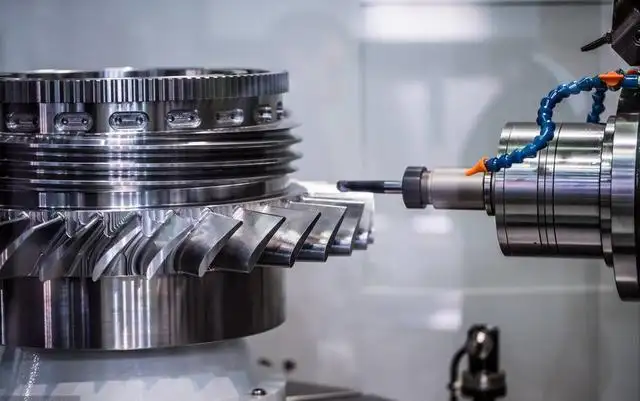

Our chief engineer of V1machining will introduce us some ways to improve the machining power of precision parts. Non-standard equipment parts processing process will appear tool wear accelerated, poor processing appearance integrity, chip cleaning difficulties and other common problems. Seriously affect the quality of such material precision parts processing, production cycle and processing costs. Non-standard […]

Methods to improve the efficiency of precision parts machining Read More »