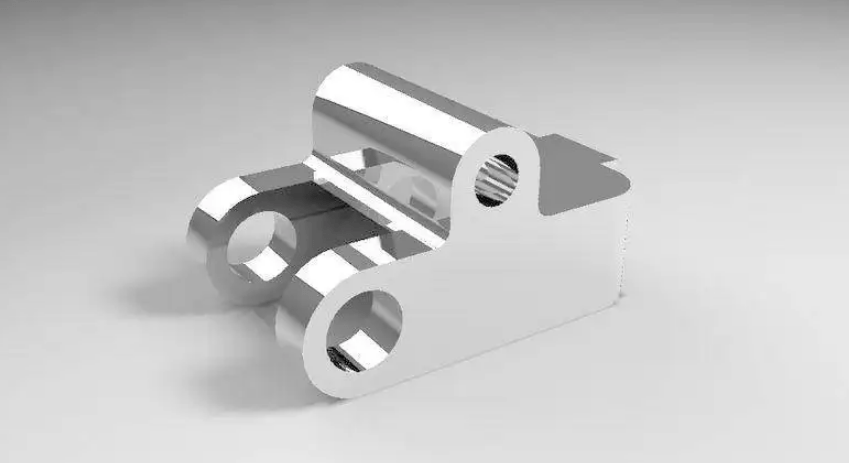

What are the requirements of CNC precision parts machining in terms of finished product appearance quality

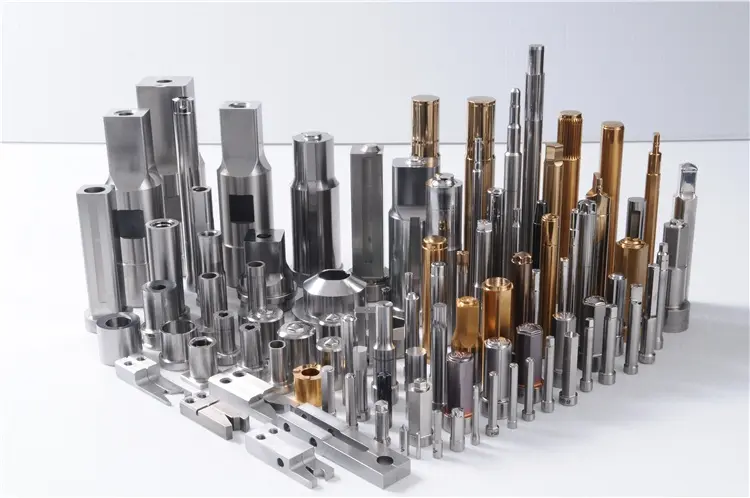

CNC machining is the computer design of CNC programs based on the appearance of the structure and material characteristics of the product drawing, through the fine CNC machine tool milling blanks to get the size of the drawing requirements of the parts. However, the surface obtained by CNC milling is not the final appearance of […]