shaft in mechanical Industry

CNC Machining Parts Solutions

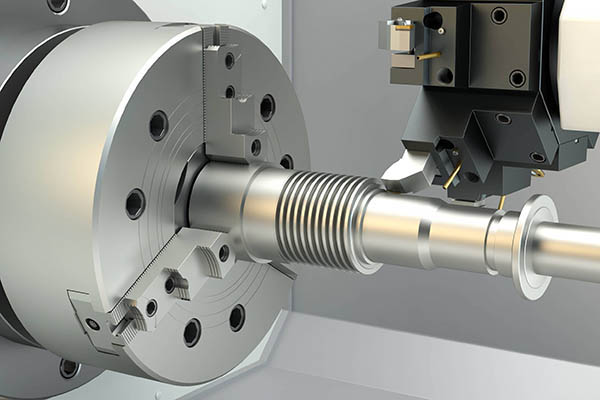

CNC Machining Services For Shaft Parts

Shaft parts are one of the typical parts frequently encountered in machines. It is mainly used to support the transmission parts, transfer torque and bear the load. Shaft parts are rotating body parts, whose length is greater than the diameter, generally by the concentric axis of the outer cylindrical surface, tapered surface, bore and thread and the corresponding end face composed of. According to the different structural shapes, shaft parts can be divided into light shaft, stepped shaft, hollow shaft and crankshaft, etc..

Cases we have done

Shaft Parts CNC Machining

V1 Machining for shaft parts, processing accuracy can reach 0.001mm, has a perfect quality system and rich experience in the design and manufacture of automation equipment and components, a complete range of equipment, a well-configured staff team, comprehensive experience, and many years of experience in cooperation with customers from various countries, and the main domestic customers are mainly listed companies. At present, the main production equipment includes CNC lathe, CNC vertical and horizontal machining center, super precision grinder, various conventional grinders, various other conventional equipment, etc. The testing equipment is equipped with various testing equipment such as Hexagon coordinate testing machine, etc. At present, the largest shaft parts can be up to ₵800*3000 mm. The company passed ISO9000 quality system in 2015.

Shaft Parts CNC Machining

Why Choose V1 Machining

Our goal is to be your reliable partner. What we are pursuing is a long-term cooperative relationship.

Offering a wide range of parts to be machined, you will receive reports just as if you were in our factory.

16 years experience in machining metal parts

V1 Machining is a ISO9001:2015 and ISO 14001:2015 and IATF 16949 certified company

Advanced equipment and professional testing, experienced engineer team

Digital scientific management to promote efficient operation of teams and suppliers

Leave A Message

Shaft parts machining process technology key points

A shaft is a cylindrical object worn in the middle of a bearing or in the middle of a wheel or in the middle of a gear, but a few are square in shape. Shaft is a mechanical part that supports rotating parts and rotates with them to transmit motion, torque or bending moment. It is generally a round metal rod, and each segment can have a different diameter. The machine for rotary motion of the parts on the shaft.

I. the shaft material

1、Carbon steel 35, 45, 50 and other high-quality carbon structural steel because of the high comprehensive mechanical properties, the application of more, including 45 steel is used most widely. In order to improve its mechanical properties, it should be normalized or tempered. Not important or less stressed shaft, it can be used Q235, Q275 and other carbon structural steel.

2, alloy steel alloy steel has higher mechanical properties, but more expensive, mostly used for special requirements of the shaft. For example, the use of sliding bearing high-speed shaft, commonly used 20Cr, 20CrMnTi and other low-carbon alloy structural steel, after carburizing quenching can improve the wear resistance of the journal; machine rotor shaft in high temperature, high speed and heavy load conditions, must have good mechanical properties of high temperature, often using 40CrNi, 38CrMoAlA and other alloy structural steel. Shaft blanks to forgings preferred, followed by steel; larger size or complex structure can be considered cast steel or ductile iron. For example, ductile iron is used to manufacture crankshaft and camshaft, which has the advantages of low cost, better vibration absorption, lower sensitivity to stress concentration and better strength.

The mechanical model of the shaft is a beam, most to rotate, so its stress is usually a symmetrical cycle. The possible forms of failure are: fatigue fracture, overload fracture, excessive elastic deformation, etc. The shaft is usually fitted with some parts with hubs, so most of the shafts should be made as stepped shafts with large cutting and machining.

II. Classification

Common shafts can be classified into crankshaft, straight shaft, flexible shaft, solid shaft, hollow shaft, rigid shaft and flexible shaft (soft shaft) according to the structure shape of the shaft. Straight shafts can be further divided into.

① Rotating shafts, which work with both bending moment and torque, are the most common shafts in machinery, such as the shafts in various reducers, etc.

② mandrel, used to support the rotating parts only bear the bending moment and do not transmit torque, some mandrels rotate, such as the axle of railroad vehicles, etc., some mandrels do not rotate, such as supporting the shaft of the pulley, etc.

③ drive shaft, mainly used to transmit torque without bearing the bending moment, such as the long light shaft in the crane moving mechanism, the drive shaft of the car, etc..

The material of shaft mainly adopts carbon steel or alloy steel, but also can use ductile iron or alloy cast iron, etc. The working capacity of the shaft generally depends on the strength and stiffness, and also on the vibration stability when the speed is high.

III. Structure

The structure of the shaft should meet the requirements of three aspects.

The parts on the shaft should have reliable circumferential fixing and axial fixing.

The shaft should be easy to process and avoid or reduce stress concentration as much as possible.

The shaft should be easy to install and remove the parts on the shaft.

Journal: The part of the shaft and bearing mating

Shaft head: shaft and rotating parts with the part

Shaft body: the part that connects the shaft head to the shaft journal

Shaft shoulder or shaft ring: the part of the shaft on the cross-sectional size change.

IV. the shaft parts of the fixed

1. Axial fixation of shaft parts

Purpose: to ensure that the parts on the shaft have a determined axial position, to prevent the parts from moving axially, and can withstand axial forces.

2.Shaft parts on the circumferential fixed

Purpose: to ensure that the shaft can reliably transfer motion and torque, to prevent the shaft parts and shaft relative rotation.

V. Common process structure on the shaft

Structure technology - the structure of the shaft should be easy to process, easy to assemble and repair the parts on the shaft, and can improve productivity and reduce costs.

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries: