How to make medical parts with CNC machining?

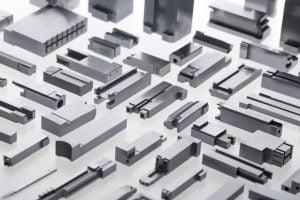

CNC manufactures a wide range of surgical instruments used in medical operations, such as trocars, bone drills and saws. When CNC machining is used, parts are typically milled using 3 to 5 shafts or turned using a moveable tool CNC lathe. The most common types of machines used in the