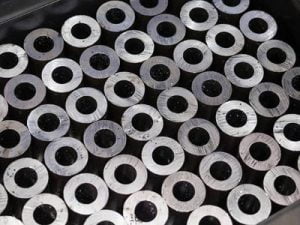

Advantages of CNC machining over 3D printing

3D printing and CNC machining are the more common production processes in the field of precision machining today. There are similarities and differences between the two, for example, CNC machining is suitable for mass production. It can create many products in a much shorter period of time, 3D printing takes