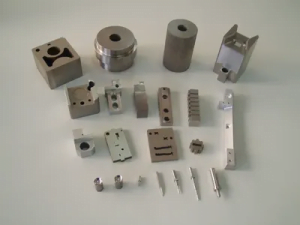

Machining of shaft parts

We know that shaft parts are one of the common parts in the machine, but also one of the very important parts, because it is about the support role of transmission components and transmission torque, then how to achieve the mechanical processing of shaft parts? First of all, we need