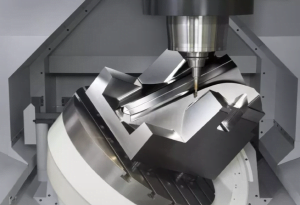

The impact of machining process on the accuracy of automotive parts

The precision of auto parts is one of the key factors affecting the overall quality and performance of the car, and is also one of the indicators measuring the level of auto parts processing technology. With the booming development of China's auto industry, the precision standard of auto parts is