Several common positioning methods for CNC machining centres

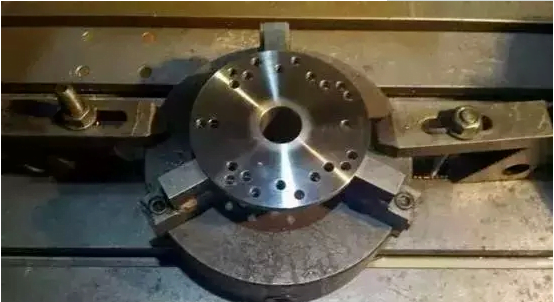

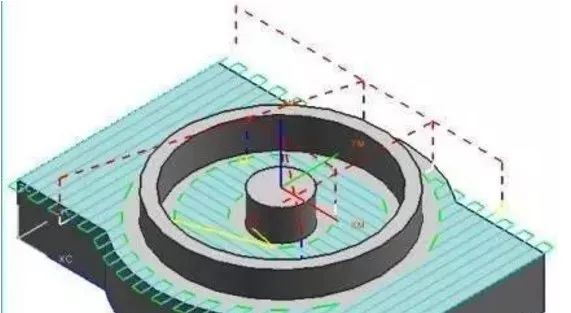

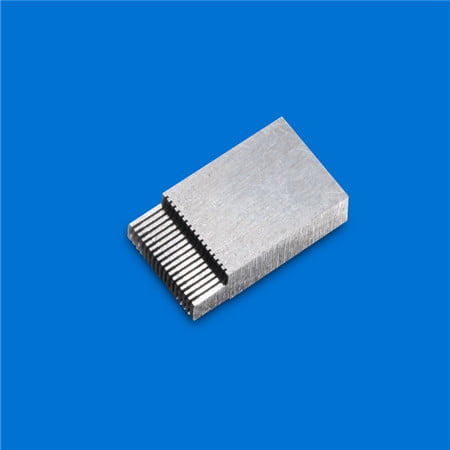

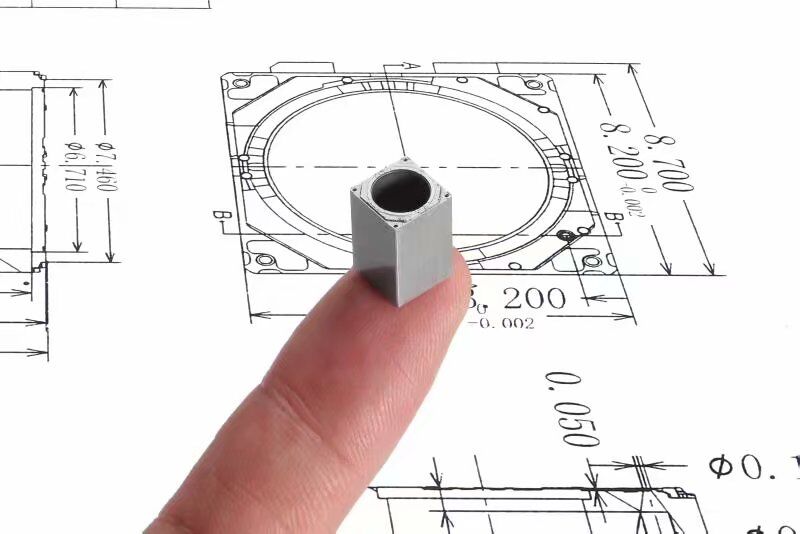

CNC machining centres, analysis of drawings, programming, work, edge finding, tool preparation, tool setting and running programs are all essential steps, one cannot be missing. In the factory, there is always some batch work is often done, we can save the program to the computer, the next time you use it directly transferred into the […]

Several common positioning methods for CNC machining centres Read More »