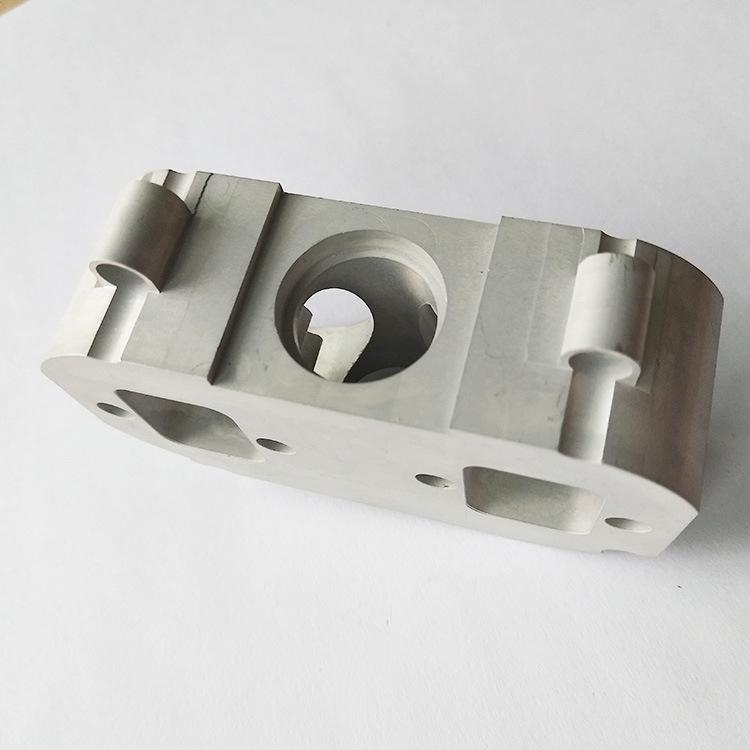

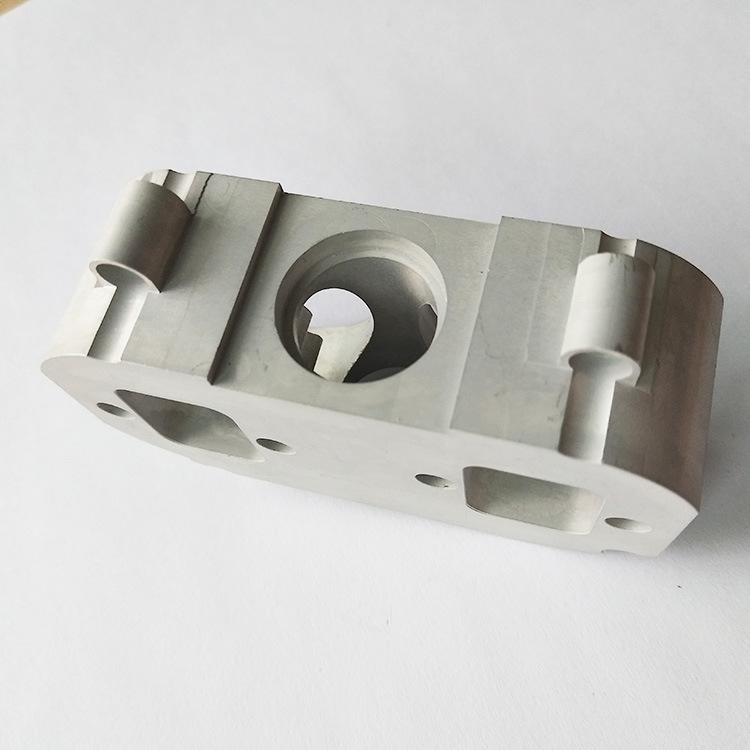

Lathe machine and its parts. For example, irregular shaped parts such as supports and forks are mostly processed by mixing multiple stations. Due to the irregular shape of the parts, ordinary machine tools can only process the parts in a decentralized manner, which requires more tooling and longer production cycle. For CNC machine tools, it is easy to process such special-shaped parts.

Lathe machine and its parts.CNC machine tools can complete the part surface composed of complex curves or surfaces. During processing, multiple coordinate axes need to be linked to carry out the process that is difficult to be completed by ordinary machine tools. The process of these parts needs to be highly concentrated, the accumulated error of part size should be small, and the assembly accuracy should be high. CNC machine tools can meet the needs of these lathe machine and its parts.

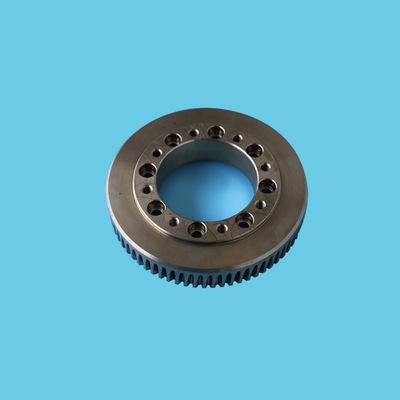

Parts of plane type and hole system; A part whose machining surface is parallel to the horizontal plane and whose included angle is the same is called a planar part. Each processing surface of such parts is a plane or can be expanded into a plane, and a special angle forming milling cutter is basically selected for processing. CNC machine tools can process distributed holes with keyways or end faces according to different spindle movements. It can also be used to machine the disc sleeve of curved surface and plate parts with more holes.

Variable angle parts; Parts whose included angle between the machining surface and the horizontal surface changes continuously are called variable angle parts. Most of these parts are aircraft parts, as well as inspection fixtures and assembly fixtures are also variable angle parts.

Lathe is mainly used to process revolving parts, such as long axis and short axis parts.

A lathe is a machine tool that mainly uses turning tools to turn rotating workpieces. On the lathe, drills, reamers, taps, dies and knurling tools can also be used for corresponding processing.

Milling machine is a machine tool that uses milling cutter to process various surfaces on workpiece.

Generally, the rotary motion of the milling cutter is the main motion, and the movement of the workpiece (and) milling cutter is the feed motion.

It can process plane and groove, as well as various curved surfaces and gears.

A milling machine is a machine tool that uses a milling cutter to mill the workpiece.

In addition to milling planes, grooves, gear teeth, threads and spline shafts, milling machines can also process more complex profiles. They are more efficient than planers and are widely used in machinery manufacturing and repair departments.