So far, the CNC machining auto parts has entered a crazy stage. It can be said that parts, as a category with large applicability, actually, for the industry, the proliferation of parts is to better equip the machine for operation.

NC machining process of CNCmachining auto parts

Design of drawings

Drawing is the beginning of a part, which is designed according to the requirements of customers, so that customers can pay more attention to you.

Selection of materials.

When we are processing, we will certainly choose materials that are suitable for it. What materials are suitable for it? In fact, materials can be said to be the core product of the whole part, so you must carefully select them.

Programming

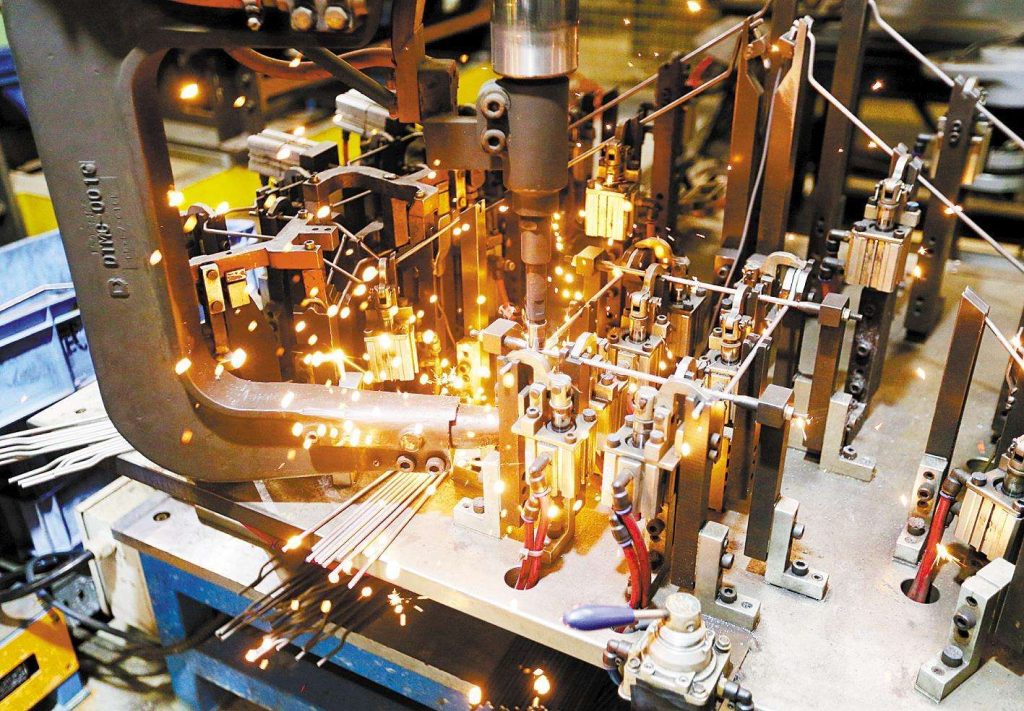

CNC lathe is a new type of equipment that can realize automatic production. At present, this equipment can realize full automatic production, which can save a lot of unnecessary expenses. It can be said that it is a purely cost saving mechanical equipment.

Operation steps during processing

No matter what parts are processed, the steps must be carried out according to the conventional process. The processing steps cannot be changed at will. Any error in this step will affect the needle bending of the whole part.

Disassembly and Application of CNC machining auto parts

Lathe

In the CNC machining auto parts

is generated due to the friction between the workpiece and the tool. In order to avoid the workpiece deformation caused by the increase of heat affecting the machining accuracy, it is necessary to cool the workpiece in time. In the existing technology, there are fewer coolant outlets.

As a result, the heat generated in the processing process cannot be taken away completely, the cooling effect is not correct, and it is inconvenient to clean the lathe feet, especially when the lathe has been used for a long time, and there are many oil stains on the surrounding site or operator's soles, the human body is still easy to fall, resulting in safety accidents and other technical problems.

Horizontal hub lathe body.

The main body of the horizontal wheel hub lathe includes a foot device and a water spray device. The water spray device includes a flow divider block and a fixed flow divider block. A number of movable nozzles are arranged on the flow divider block. The movable nozzles include the base of the nozzle. Water inlet channels are arranged in the base of the nozzle. Sealing rings and rotating nozzles are also arranged on the base of the nozzle. Water inlet channels are arranged in the rotating nozzle. The water inlet channels are connected with the water inlet. Fixed flow divider blocks are arranged with a number of fixed nozzles.

The foot device includes the foot pedal

A number of round iron pillars are set on the foot pedal bottom plate, a foot pedal top plate is set on the round iron pillar, a number of horizontal anti slip strips are set on the foot pedal top plate, a number of longitudinal anti slip strips are set on the horizontal anti slip strips, and the horizontal anti slip strips and the longitudinal anti slip strips are fixed on the foot pedal top plate through mounting screws; The foot pedal is connected with the foot pedal mounting plate, and two waist shaped mounting holes are arranged on the foot pedal mounting plate.

The horizontal wheel hub lathe has a higher working efficiency by setting a foot device and a water spraying device.

The water spraying device is equipped with several movable nozzles on the diversion block, which can be adjusted according to the actual workpiece.

In addition, a number of fixed diversion blocks are set under the beam of the CNC machine tool, and fixed water nozzles are set on the fixed diversion blocks, so as to wash the iron scraps flying randomly after processing in the form of water curtain in the processing workpiece.

Water spraying device for horizontal wheel hub lathe

In the process of clamping and disassembling the contact surface between the datum plane of the part and the fixture, the fixture can be washed in time to ensure the smooth clamping of the processing part, and prevent the iron scraps during processing from scratching the workpiece again, and timely wash the protection inside the machine tool.

The foot treading device makes the horizontal and vertical anti slip strips form a vertical network by setting the horizontal and vertical anti slip strips. The anti slip performance is very good, and the horizontal and vertical anti slip strips can be disassembled, so the cleaning is very convenient.