Both CNC machining centers and CNC lathes belong to CNC machine tools. Their processing performance is higher than that of ordinary machine tools. The advantage is that they have a high degree of automation. The lathe is called CNC lathe, the milling machine equipped with the CNC system is called the CNC milling machine, and the tool magazine is installed on the CNC milling machine, then it is called the machining center.

However, CNC lathes and CNC machining centers are different in the number of motion axes. CNC lathes control two motion axes, while machining centers are at least three-axis control linkage or four-axis or five-axis linkage.

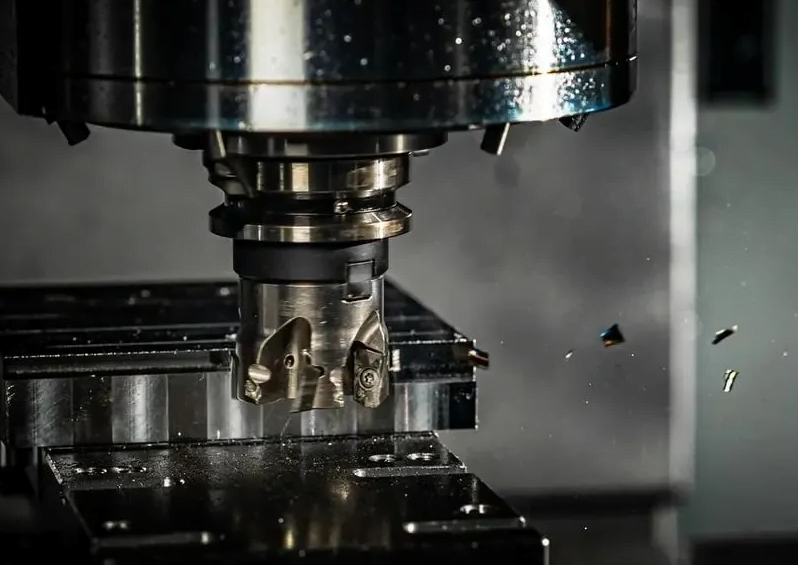

Looking at the difference between the two in terms of the processing range, CNC lathes are mainly used to process revolving parts, while machining centers are used to process complex types of parts such as surface grooves and so on.

From the perspective of the tool magazine form, the CNC lathe does not have a tool magazine but has a tool holder on the bed. The CNC machining center is equipped with a manipulator with a tool magazine, and can be equipped with tools of various processing forms.

The fundamental difference between a CNC machining center and a CNC lathe is that the machining center has the ability to automatically exchange machining tools. By selecting different purpose tools installed on the tool magazine, multi-process machining can be realized by automatically exchanging machining tools in one clamping. This machining process reduces the number of workpiece installations and ensures machining accuracy. The CNC lathe can complete one process of processing.

The basic codes of programming of the two types of CNC lathes and CNC machining centers are mostly the same, but some special instructions may not be common between systems. Specific circumstances should be treated according to actual requirements.

Through the comparison of the above aspects, it is not difficult to see that the machining center has powerful functions. It concentrates the functions of milling, grinding, drilling and tapping, and is a CNC machine tool with comprehensive processing functions. It can also be understood that choosing a machining center machine tool to make any hardware products and mold products can complete its required processing tasks. The advantages of the processing function of the machining center are not only these, it is easy to operate, high precision, good performance, high efficiency, low manpower and long service life.