CNC Milling Services

China Top CNC Milling Supplier & Manufacturer – V1 Machining offers worldwide clients affordable, rapid, high precision custom CNC Milling Services, variety of materials available to meet the needs of different industries!

- Machined prototypes in as fast as 1 days.

- 50+metals and plastics

- Tolerances down to +-0.001mm

- ISO 9001:2015、ISO 14001:2015 and IATF 16949

Advanced Precision CNC Milling Process

Starting from designing a CNC milling part drawing or geometry with CAD software, then CAM software converts the file to CNC machine program, which can dictate the machine what to do and how to do. CNC milling services apply computerized technique to complete the manufacturing as the following basic production stages:

- Designing a CNC Milling CAD model

- Converting the CAD model into a CNC milling program

- Setting up the CNC milling machine

- Cutting small pieces off the block material to obtain approximate shape

- Executing the CNC milling operation with higher precision and accuracy

V1 CNC Milling Services Capabilities

With decades of experiences and expertise in CNC machining services, we providing OEM milling service and products involving precision milling, thread milling, metal milling, plastic milling, etc.

- Six advanced CNC machines at the V1 CNC Milling Center:

- Number of CNC milling machining centers: 6

- Number of axes: 3-axis or 5-axis

- Product dimension 3-axis milling machines: up to 500 x 500

- Product dimension 5-axis milling machines: up to Ø 300

CNC Milling Parts FAQs

V1 machining is a professional China CNC milling company provides superior precision CNC milling services with advanced machines including CMC milling center and milling machining centers from the general 3-axis to 5-axis and accomplished machinists.

What parts can be made by CNC milling?

Modern CNC milling machines can be configured as horizontal or vertical machining centres and produce distinct components from plastics, ceramics, composite materials, and metals. Automatic tool changers, tool carousels and magazines, coolant systems, and enclosures are among the technical elements included.

Difference CNC turning and CNC milling?

Turning operations are performed by rotating the workpiece and using a stationary cutting tool, and milling operations are performed by rotating the cutting tool and leaving the workpiece locked in place.

What types of materials do CNC mills use?

The most common materials used in CNC milling are metals such as brass, Titanium, aluminium or steel, and plastics such as PVC, ABS, polycarbonate and polypropylene.

What Are Tolerances?

In short, tolerances are measurements that signify the level of precision needed for a part that you want to manufacture. Specifically, machining tolerances indicate the degree of variation permitted in a part’s final dimensions or measured value.

CNC Milling and Turning Service

a compound machining technology in which the cutting tool and workpiece are both rotating, to produce complex curved or special-shaped parts through designed multiple kinds of tasks.

What kind of surface finish CNC machining?

Due to the spinning motion produced by the CNC milling machine’s cutter, the surface finish of CNC machined parts will have visible toolmarks. If you require a smooth, unblemished finish to your part, we recommend choosing a secondary finish: grained finish or powdercoat.

Products

.01

Mechanical Parts Machining's Capacity

For processing orders of mechanical part, all are produced and processed by “Mechanical Parts Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

72

Production equipments

49

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.02

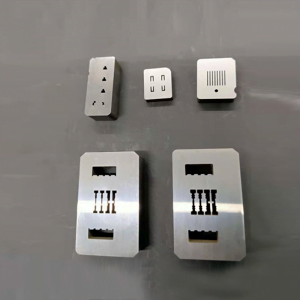

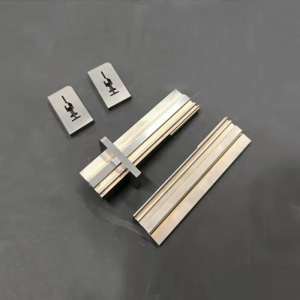

Precision Mold Parts Machining's Capacity

For processing orders of precision mold parts, all are produced and processed by “Precision Mould Parts Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

66

Production equipments

24

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

.03

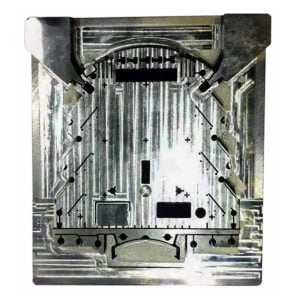

Large Parts Machining's Capacity

For the processing and customized orders of Large parts, the “Large CNC Machining Processor”, a sub-factory of V1 INDUSTRIAL GROUP in China.

59

Production equipments

154

Testing equipments

0.001mm

Machining accuracy

16+

Industry experience since 2006

CNC Manufacturing Materials

Choose the right materials for your manufacturing needs from prototype to production

Applications Industries of Parts CNC Machining

V1 machining is a CNC company offering services suitable for mass production of high-precision mould parts, large Die parts and various mechanical parts, such as components for cell phones, medical devices, optical equipment, automobile, the lighting industry, office equipment, etc. We know that CNC machining has become the most basic, extensive and important technology in the mechanical manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection. The CNC machining applications involves the following industries:

Custom CNC Milling Services

If you need any metal and plastic materials cnc Milling and custom surface treatment services