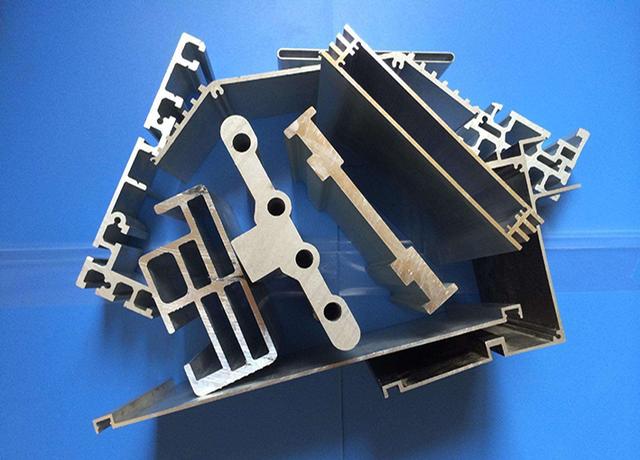

With China's ongoing large-scale infrastructure and accelerating progress in industrialization, the production and consumption of aluminium profiles has grown rapidly and has now become a world-class scale aluminium profile production base and consumer market. China's industrial aluminium profiles account for about 30% of the total application of aluminium profiles, mainly used in the automobile manufacturing industry, rail transportation industry, equipment and machinery equipment manufacturing industry, etc.

With the development of the industrial aluminium profile industry, the CNC processing industry for industrial aluminium profiles is also paying more and more attention to the study of the aluminium profile processing process, in particular the investment in research and development of enterprises and the in-depth study of customer needs. The use of CNC machine tools for processing industrial aluminium profiles has now become a processing trend. The new CNC machining technology in industrial aluminium profile processing comes from innovative CNC machining procedures, i.e. turning the previous manual work of ordinary machine tools into computer-controlled operations. However, manual machining experience is still required.

The determination of the route for CNC machining of industrial aluminium profiles generally follows several principles: firstly, to ensure the accuracy and surface roughness of the workpiece, then to make the machining route shorter and to shorten the time required for the journey, thus increasing the efficiency of the process. The second is to simplify the workload of numerical calculation as much as possible, thus simplifying the processing process, and for some reused procedures, a database needs to be established for grouping. Comprehensive to have the strength of the CNC machining factory can ensure the accuracy and efficiency of CNC machining.