CNC Turning Services

- 16 years experience in machining metal parts

- Advanced equipment & professional testing,quality assurance

- Digital management process,amazing efficiency

- Tolerances down to +-0.001mm

CNC Turning Services

V1 Machining, a quality CNC Turning Services company, has cooperated with many companies in the United States, Germany, and Canada for up to 10 years. Fast DMF assessment, and efficient service, is the beginning of our cooperation.

Our Advantages

- V1 have professional production equipment and testing equipment.

- High quality management system including ISO 9001:2015, ISO 14001:2015, IATF 16949 certification to ensure high level and high precision parts.

- Capable of machining high precision parts with tolerances up to 0.001 mm

- We have advanced production management and order tracking system to ensure efficient production, full tracking and on-time delivery of orders.

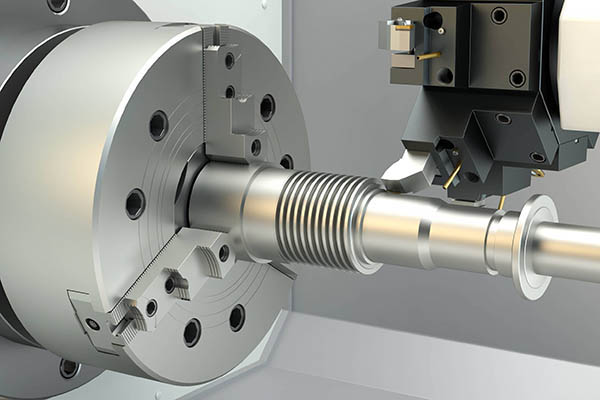

Custom CNC Turning Services--Advanced production equipment

V1 Machining is an experienced supplier, manufacturer and exporter of precision CNC Lathe services in China, focusing on providing the best OEM CNC Lathe services.

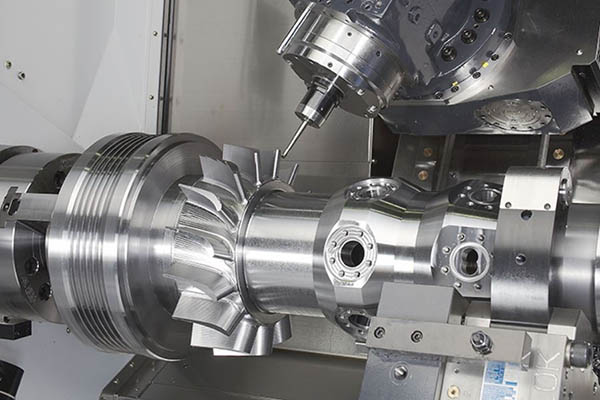

Providing quality low-cost CNC lathe parts, CNC lathe parts or high-precision machined components. By operating an impressive array of state-of-the-art lathes such as CNC lathes, 3-axis CNC lathes, slant bed CNC lathes, CNC lathe shops, slant bed CNC lathes and other equipment, thus enabling fast and efficient custom production of the turned parts required by our customers.

Precision CNC Turning Parts from OEM China - Capable of Turning a Wide Range of Materials

Our advanced CNC turning centre routinely works with various materials, including copper, brass, stainless steel, carbon steel, aluminium, and titanium. We can always choose a suitable precision turning process to reach your requirements. Our custom CNC machining services ensure our customers receive the highest quality CNC-turned parts. Send your inquiry or draw fast to get an online CNC quote.

FAQs of CNC Turning

Is My Part a Good Fit for CNC Turning?

The following parts are a good fit for CNC turning:

Rotary parts with high precision requirements.

Rotary parts with complex surface shapes.

Rotary parts with lateral machining.

Ultra-precision and ultra-low surface roughness parts.

Parts with special threads.

How to Reduce the Cost of Machining Parts?

The main costs related to CNC machining can be divided into machining time, start-up cost, material cost, and feature cost. To reduce costs, you need to understand the impact of these factors on costs.

– The best way to reduce machining time is to design features that can be processed quickly, such as by selecting the correct inner corner radius, reducing the cavity depth, increasing the wall thickness, limiting the thread length, and designing holes of standard size.

– The material cost can be reduced by considering the size of the required blank and the cost and machinability of bulk materials (softer alloys process faster).

– Start-up costs can be reduced by reducing the number of part rotations or repositioning required to complete the part, such as dividing the geometry into multiple parts that can be assembled later.

– Using tolerances only when strictly necessary, deleting all text and letters, and avoiding multiple surface treatments can reduce feature costs.

Read more detail in our complete guide on how to reduce the cost of CNC machining parts.

What Parts Can Be Made with CNC Turning?

CNC turning is used for creating a variety of parts, including auto parts, knobs, tubes, gears, toy parts, flywheels, crankshafts, hubs & disc cams. It is most often used to manufacture CNC parts online for automotive, aerospace, medical, and other industries.

Heat Treatment of Precision Turned parts

Heat treatments can be applied to precision CNC-turned parts to improve their key properties, such as hardness. Heat treatment will apply to metal parts throughout the manufacturing process.

– Hardening is used to harden the material, make it stronger, and decrease flexibility.

– Annealing: heats metal parts to a very high temperature and then slowly cools to achieve the desired microstructure.

– Normalizing: used to relieve internal stresses created during machining service.

– Quenching: heating the metal to a very high temperature, followed by a rapid cooling step.