Connector mold parts|Connector mold insert processing involves which occupations? In order to let us have a deeper understanding of some. The following V1machining editorial to us about the list.

Connector mold parts|connector mold insert processing involved in which professions

Connector mold inserts are mainly used in cars, medicine, agriculture and other fields. Connector general refers to a variety of electronic components between the interface unit, the primary as a single wafer to the circuit board, between the circuit board and the circuit board to the box of electronic signal interface and transmission.

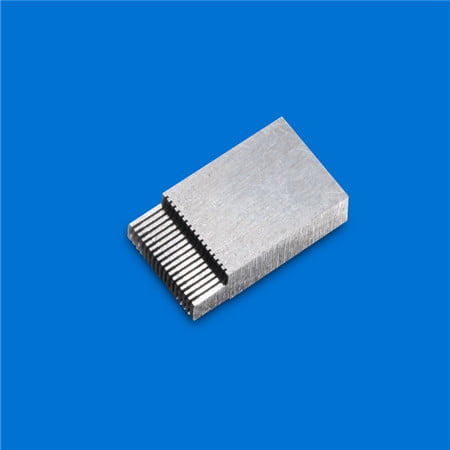

Connector mold inserts are mainly processed by grinding machine, electrical discharge, wire cutting to reach its fineness. Connector mold inserts through grinding and polishing after the appearance of low roughness, scale accuracy can reach 0.025um, the appearance of wear resistance progress, fatigue strength progress, scale accuracy progress, sphere and cylinder roundness up to 0.1um.

V1machining is a professional supplier of connector mold parts|connector mold insert processing, mold insert processing, precision mold parts processing, precision plastic mold processing, etc.. Aucai fine mold editor can refer to the world brand specifications manufacturing, processing, inspection according to customer requirements. And we can manufacture according to the national standard GB, Japanese standard JIS, German standard DIN, American standard AISI and other world occupational norms. If you want to know more, you can click online consultation, our company will give specific answers to your questions.