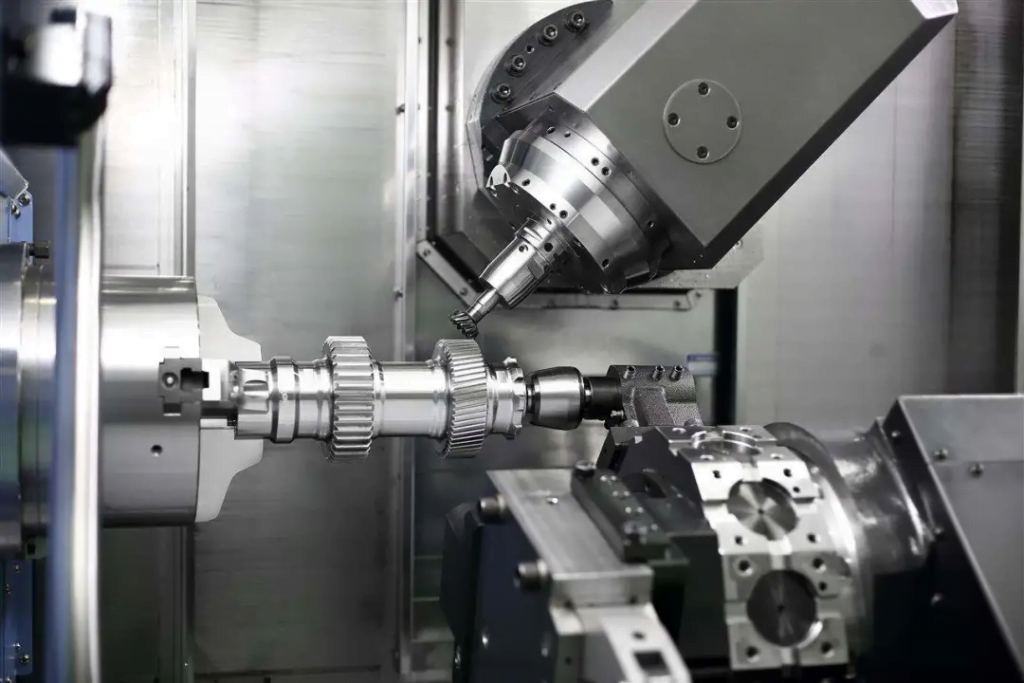

Because of the complex shape and structure of aircraft CNC machine parts, various materials and strict machining accuracy requirements, aviation manufacturing has always been one of the industries with highly intensive advanced technology.

The complexity of aircraft CNC machine parts manufacturing is mainly reflected in the following aspects:

(1) Usually with complex theoretical surface shape, crisscrossing reinforcement structure, thin wall structure with small thickness, not only complex shape, but also holes, holes, grooves, reinforcement, etc., the process rigidity is poor.

(2) Modern aircraft has long life and high reliability requirements, which makes the quality control requirements of parts surface more stringent; The dimensional accuracy and surface quality of parts are required to be higher and higher.

(3) In order to improve the strength and reliability of the parts, the main use of the overall blank parts and the overall thin-walled structure, the structure is complex, large material removal, high precision and surface quality requirements, long processing cycle.

(4) Parts of the material for high strength steel, aluminum alloy, titanium alloy, high temperature alloy and composite materials and other difficult to process materials.

Due to the above characteristics of aircraft CNC machine tool parts, the aviation manufacturing industry has put forward the following requirements for CNC machine tool equipment:

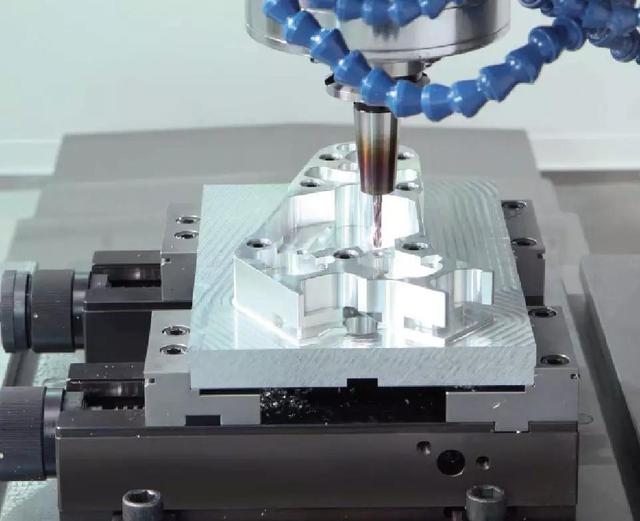

Thin-walled parts have been widely used in aviation parts because of their light weight, material saving and compact structure.

However, due to poor rigidity and weak strength, thin-walled parts are very easy to deform during processing, which increases the shape and position error of the parts and makes it difficult to ensure the processing quality of the parts. The use of high-speed CNC cutting equipment can greatly improve this situation, because the cutting force decreases with increasing cutting speed.

Most of the heat generated by cutting is taken away by the chip, in the range of high speed cutting machine tool excitation frequency away from the natural frequency range of the process system, and can minimize the radial cutting force and thermal deformation in the processing of the above characteristics are helpful to reduce the deformation of the workpiece, improve the processing accuracy and surface quality of thin-walled parts.

For aircraft structural parts, it is also the main field of high-speed machining, especially in the cutting of aluminum alloy structural parts and composite components.

For high temperature nickel base alloy, titanium alloy and high strength structural steel by modern aviation products such as a lot of difficult-to-machine materials, because the material strength, high hardness, impact resistance, easy processing of hardening, high cutting temperature and tool wear serious, only USES the high speed cutting technology, can effectively reduce the tool wear, Greatly increase productivity and improve the surface quality of parts.