Physical environment

In the process of machining process to produce automotive parts, the physical environment has the greatest impact on the accuracy and is irreversible.

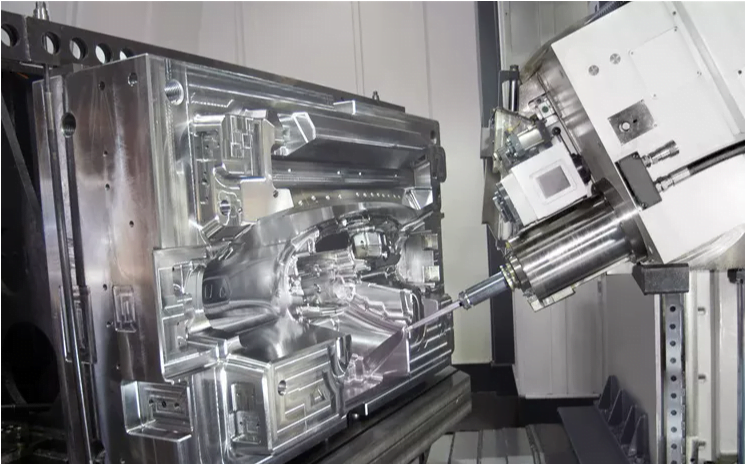

Modern machining usually uses mechatronic CNC machine tools, which need to be set according to the production requirements before processing, and once the parameters are set wrong, the error with the parts processing requirements will directly affect the accuracy.

Thermal deformation

Thermal deformation is a frequent phenomenon affecting the accuracy of processing production, in the processing of automotive parts, two kinds of thermal deformation can occur, one is caused by the tool, the other is the processing of heat deformation.

Among them, the tool in the high-frequency cutting process, due to the force and repeated friction generates a lot of heat, and the process of contact with the processing object, the transfer of heat, when more than the upper limit of the processing object tolerance, it will make the processing object deformation, resulting in the final part accuracy is not up to standard.

Deformation by force

During the machining process, the workpiece itself has the weight to produce a certain gravity, the tool in the process of running a certain cutting force and friction, machinery and equipment running too long will produce a certain squeezing pressure due to deformation, these external forces can act on the processing object, resulting in different degrees of deformation of the processing object, so as not to ensure accuracy.

Geometric error

There are many factors affecting the accuracy of the part machining process, and geometric errors have a high frequency, the impact of serious features, geometric errors and machine tool spindle rotation related to the appearance of.