In today's manufacturing industry, CNC processing position is very important, promoting the development of manufacturing industry in our country. Those of you who know CNC machining know that the cutting tools we use include tools, abrasive tools and abrades, etc., which are used to cut the blanks or excess materials on the workpiece to obtain the designed geometry.

The choice of tool is very important for CNC machining. Because whether die hand plate processing or parts processing of small batch production and CNC machining center operation procedures are inseparable from the choice of tools, and different operating environments need CNC machining tools are different.

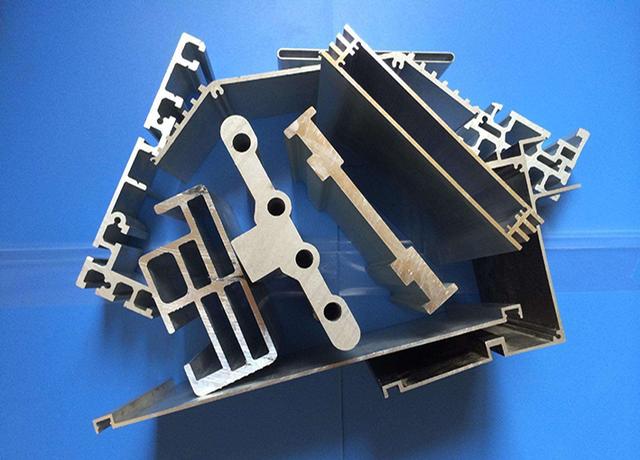

One, five kinds of CNC machining tool introduction:

The drill bit

A cutting tool for drilling holes, often used in CNC machining centers and drilling presses. According to the diameter and depth of the hole, the Nuobaine CNC machining master has subdivided a variety of drill bits, such as oil hole drill which can improve the efficiency of chip removal, and long gun drill which is suitable for drilling deep holes, to meet the needs of different customers.

tap

A cutting tool used to cut threads .Tapping holes with taps is called "tapping". It is an indispensable tool for machining mechanical parts with more threads.

reamer

A tool used for precision machining drilling diameter and surface roughness, automotive engine parts, aircraft parts and other parts of high precision will often use reamer to repair the hole, to ensure the accuracy of the hole.

tool

A cutting tool with a chip edge at the top and one of the most widely used cutting tools, often used in lathes and turning centers. It cuts into the rotating workpiece to scratch the metal surface.

hob

Gear hobbing machine, gear cutter and other gear processing machinery used special tools, mainly used to process gear or tooth workpiece.

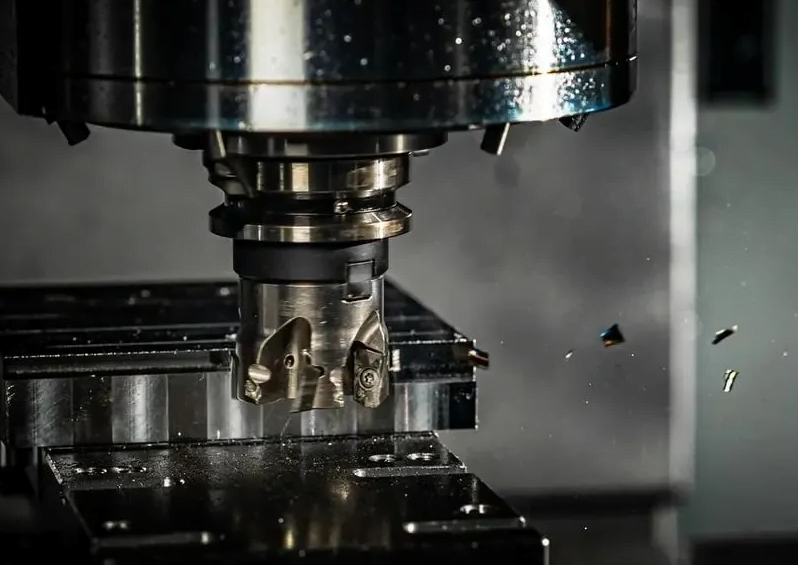

milling cutter

Milling cutter is often used in CNC machining center and milling machine processing of cutting tools, which is a representative tool is the end milling cutter tool, it can effectively cut the plane of the workpiece, side, groove and slit of the spare parts, is very popular with CNC machining manufacturers, can efficiently complete the needs of customer customization.

CNC precision machining technology six advantages:

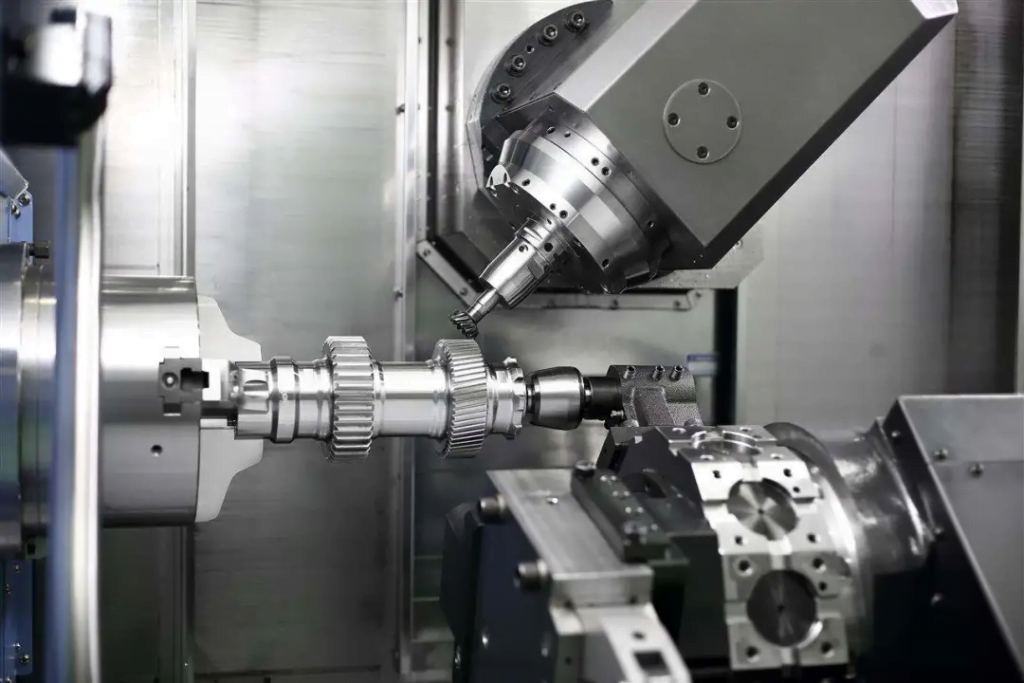

CNC precision machining usually refers to the computer digital control of precision machinery CNC machining, lathe CNC machining, milling machine processing, CNC machining boring and milling machine.

CNC precision machining can produce many types of complex parts with high precision, quality assurance can be controlled by CNC machining machines and tools including lathes, grinders, and milling machines. The six advantages of CNC precision machining are as follows:

1,In order to catch up with the customer's customized quantity, we have greatly reduced the number of tooling. The milling machine does not need complex tooling for the processing of parts with complex shapes. If you want to change the shape and size of parts, only need to modify the CNC machining program of parts, suitable for new product development and modification.

2, CNC machining quality is stable, machining precision is high, repeat precision is high, adapt to the machining requirements of aircraft.

3,multiple varieties, small batch CNC machining situation of high production efficiency, can reduce production preparation, machine adjustment and process inspection time, and because of the use of the best cutting amount and reduce the cutting time.

4,It can process complex surface that is difficult to be processed by conventional methods, and even can process some machining parts that cannot be observed.

5, the arrangement of the work step is more detailed, this is because in the CNC machining process of ordinary machine tools do not have to consider the problem, such as the arrangement of the work step in the process, the knife point, the knife point and the determination of the processing route, etc., in the preparation of CNC machine tools CNC processing technology can not be ignored.

6, CNC precision machining efficiency, high processing accuracy, low labor intensity, strong adaptability to different workpiece.