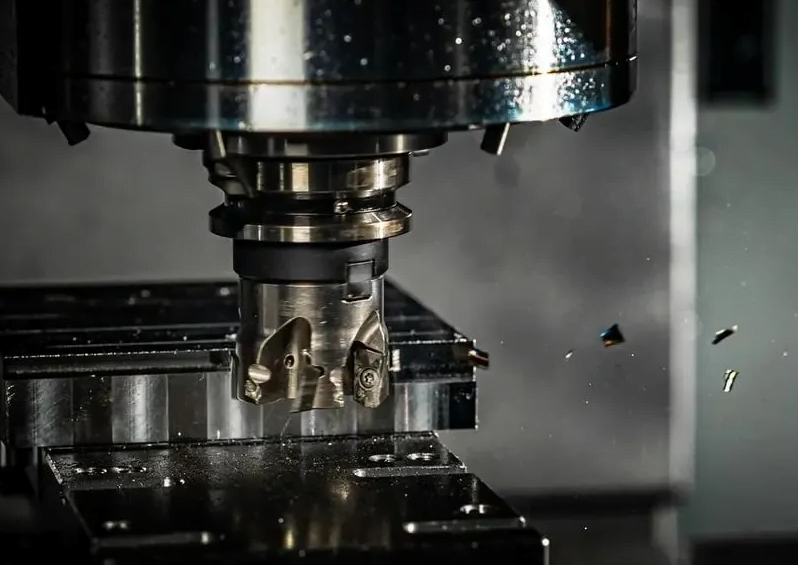

CNC CNC parts processing has been widely used in the machining industry. What are its characteristics that can convince the entire processing industry? Today, V1machining brings you together to reveal the four characteristics of CNC CNC machining.

1. High processing efficiency, which is also an obvious feature of CNC machining compared to traditional processes.

2. Stable quality

The feed route of finishing is basically carried out in sequence along its part contour, therefore, the key point of determining the feed route is to determine the feed route of rough machining and idle travel. The products manufactured by CNC machining are not only stable in quality and high in precision.

CNC CNC parts processing

3. Simplify processing procedures and minimize processing equipment. CNC machining CNC lathe feed processing path refers to the path that the turning tool moves from the tool setting point (or the fixed origin of the machine tool) until it returns to this point and ends the processing program, including the cutting processing path and the cutting-in and cutting-out of the tool, etc. Non-cutting idle travel path. Using CNC numerical control processing, the processing steps are greatly simplified and the processing equipment is greatly reduced, which saves the cost for the company. CNC machining is highly targeted. If the size of the part is changed, it only needs to be modified by programming.

Fourth, it can process complex parts. CNC machining is also suitable for complex parts that are difficult to machine, and the quality is guaranteed.

V1machining is a company specializing in the processing of precision machinery CNC parts and non-standard parts. It is equipped with CNC machining centers, CNC lathes, wire cutting, milling machines, grinding machines and other processing equipment. It is good at CNC milling and machining centers and other precision parts batch processing. Cooperate with customers' various small-scale requirements, respond quickly, and produce excellent products at low cost to achieve customers.