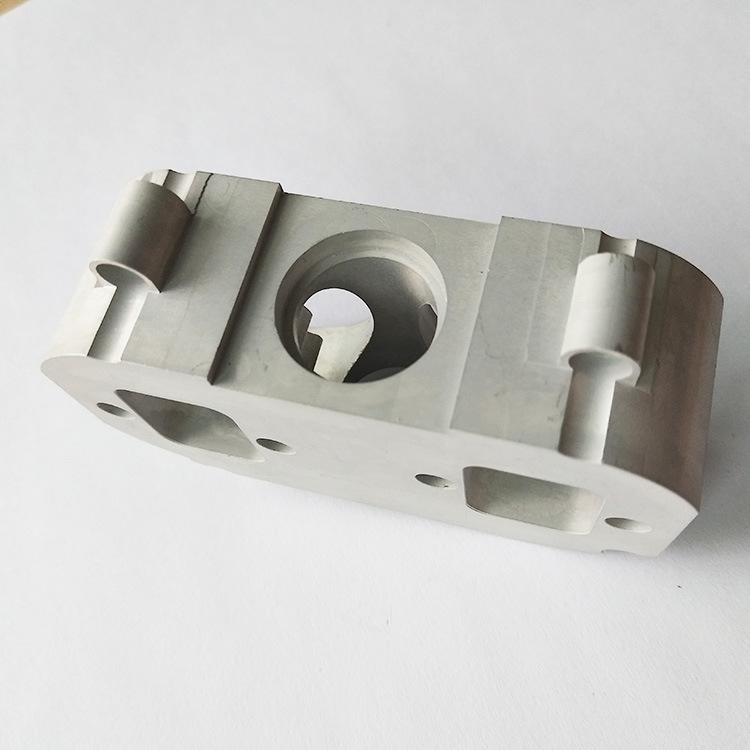

Shaft is one of the typical mechanical parts, which refers to the rotating element with the length greater than the diameter. The cross section is usually circular. The machined surface is usually located on the inner and outer cylindrical surfaces, conical surfaces, threads, splines, grooves and transverse holes. This article will mainly introduce the knowledge of precision shaft machining.

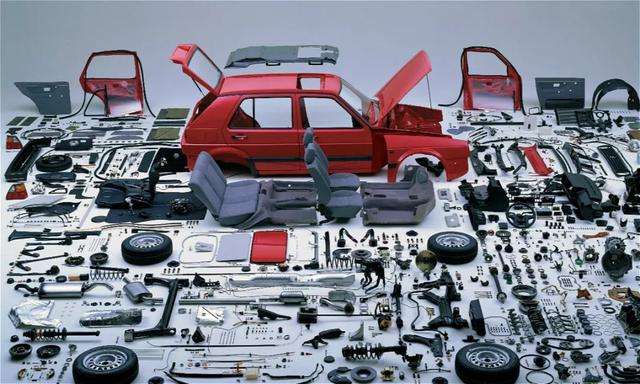

Shaft plays a vital role in most rotating equipment. Because the size has a great influence on the characteristics of precision shaft machining, the design and prototype manufacturing of the shaft are very important. Correct precision shaft machining services can produce different diameters and lengths to ensure strict tolerances.

The CNC machine controlled by computer is used for precision shaft processing, which can rapidly complete the prototyping and manufacture parts and components within a short delivery time. Depending on the exact application and the required parts or components, different machines can be used, including CNC turning, CNC lathe, CNC milling, CNC drilling, etc.

In general, very precise dimensions can be achieved automatically.

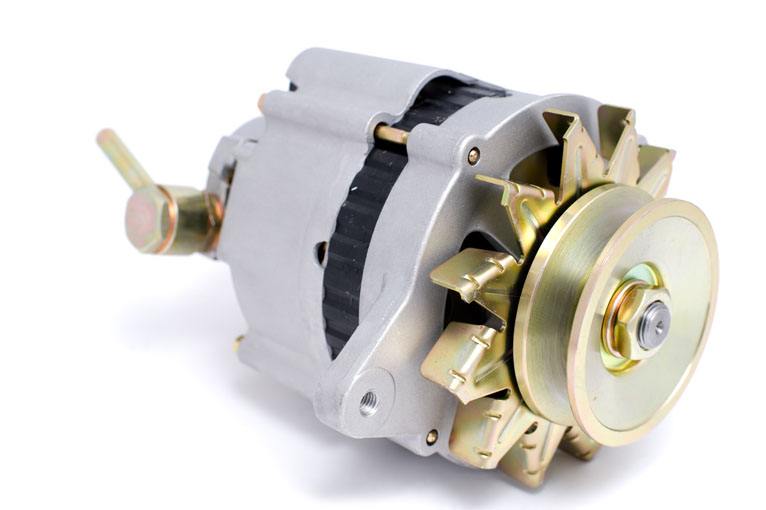

Precision shaft machining usually requires computer numerical control or CNC programming, which can transform the unique design into a variety of precise shapes. In industrial products, shaft parts are suitable for maintenance operation of one or more CNC machining parts. Shaft part is one of the typical parts often encountered in hardware accessories. It is mainly used to support transmission parts, transmit torque and bear load. According to the structure of shaft parts, they can be divided into optical shafts, stepped shafts and special shapes. Three types of shafts; Or solid and hollow shafts.

Manufacturing high-quality shafts, the following are some examples provided by precision machining workshops: hydropower: prefabricated shafts for power generation, whether wind, steam, oil or natural gas. Marine: Shafts for marine, bridge and barge applications. Marine propellers: Together with marine propellers, precision shaft machining services are used to manufacture parts and components, such as threaded shafts, pinion shafts, pump shafts, etc. Medical: Processing services produce shafts for orthopedic knee surgery.

In order to ensure high performance, efficient function and even safety, accurate CNC machining is essential. Finished products are used in applications that affect the public. Therefore, we need to consider CNC precision machining workshop that can ensure excellent shaft manufacturing quality.

The main surface of precision shaft workpiece is the cylindrical surface. The accuracy of the hollow shaft inner hole is not very high, while the secondary surface accuracy of the threads and splines on the precision spindle is very high. Therefore, the machining path of shaft parts mainly considers the machining sequence of excircles and reasonably increases the machining of secondary surfaces. The production and processing routes of CNC machining shafts with different precision and materials are as follows.

Shafts made of carburized steel: material preparation ->forging ->normalizing ->drill tip hole ->rough turning ->semi finish turning, finishing ->carburizing and quenching, low temperature tempering ->rough grinding ->secondary surface treatment ->fine grinding.

Shafts made of carburized steel: material preparation ->forging ->normalizing ->drill tip hole ->rough turning ->semi finish turning, finishing ->carburizing and quenching, low temperature tempering ->rough grinding ->secondary surface treatment ->fine grinding.