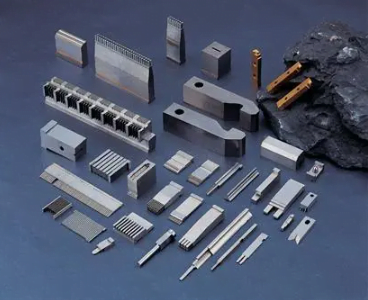

High precision mold parts in addition to the work required to have a high enough strength and toughness, its surface properties are critical to the work performance and service life of high precision mold parts. The improvement of these properties, relying solely on the improvement and enhancement of the base material is very limited and uneconomical, and through the surface treatment technology, can often receive twice the result with half the effort, which is precisely the reason why the surface treatment technology has been rapidly developed. Mold polishing technology is an important part of the mold surface engineering, is an important process of post-treatment in the mold manufacturing process. Because of the domestic polishing process technology and materials and other aspects still have certain problems, so such as fool camera lens injection mold, CD, VCD disc and tool transparency requirements of high injection mold is still a large part of the dependence on imports.

Mirror mold material is not only a matter of chemical composition, but more importantly, smelting requires the use of vacuum degassing, argon gas protection ingot, vertical continuous casting and rolling, flexible forging and a series of advanced processes, so that the mirror surface mold steel with fewer internal defects, impurities fine particle size, high degree of dispersion, fine metal grain size, good uniformity and a series of advantages, in order to achieve the requirements of polished to mirror surface mold steel. Surface treatment technology of mold parts is a system engineering to change the morphology, chemical composition, organizational structure and stress state of the surface of high precision mold parts through surface coating, surface modification or composite treatment technology to obtain the required surface properties. Nitriding process has gas nitriding, ion nitriding, liquid nitriding and other ways, in each nitriding way, there are several nitriding techniques, which can adapt to the requirements of different workpieces of different steel grades. From the way of surface treatment, it can be further divided into: chemical method, physical method, physical-chemical method and mechanical method.

It is worth noting that the mold surface polishing is not only affected by the polishing equipment and process technology, but also by the influence of the mirror degree of the mold material, which has not yet attracted sufficient attention, that is, the polishing itself is subject to the constraints of the mold material. Although aimed at improving the surface performance of precision mold parts of the new treatment technology continues to emerge, but in the manufacturing of high precision mold parts is mainly used in nitriding, carburizing and hardening film deposition. Because nitriding technology can form excellent performance surface, and nitriding process and high precision mold parts steel quenching process has good coordination, while the nitriding temperature is low, after nitriding does not need intense cooling, high precision mold parts deformation is very small, so the surface strengthening of high precision mold parts is the use of nitriding technology earlier, but also the most widely used.