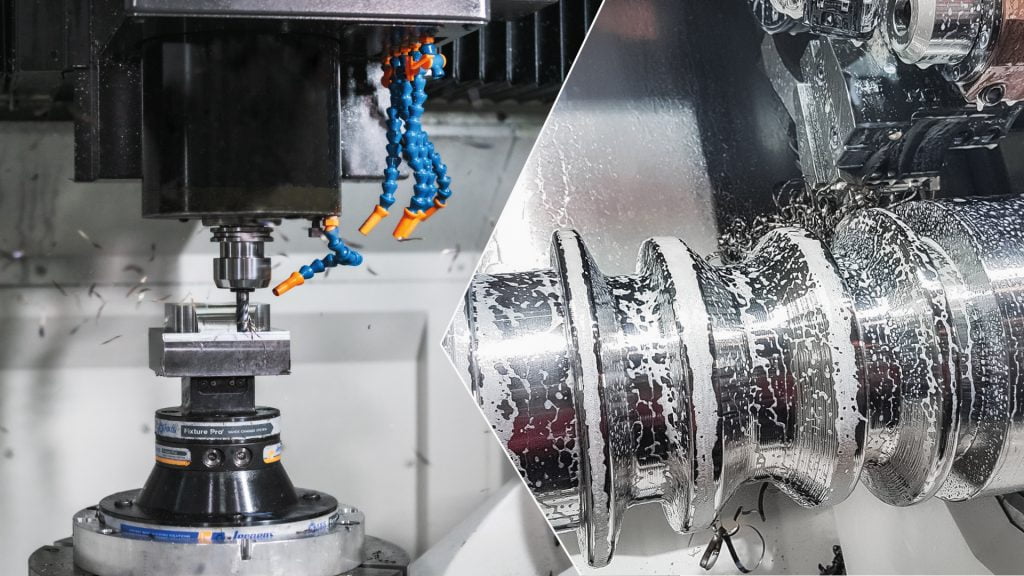

CNC machine tools to complete the machining process has incomparable characteristics of ordinary machine tools, such as substantially improve productivity, with higher machining accuracy and automation, etc. With the rapid development of automotive, aerospace, aviation, national defense and other industries, as well as the application of new materials such as aluminum alloy, the CNC machine tool processing requirements are increasingly high.

Five-axis CNC machining technology has developed to today, its processing quality, efficiency and stability, can fully meet the requirements of product production.

Its processing products are also widely used in different industry fields such as rail transportation, aerospace, automotive, moulds, wind power, new energy, new materials, etc., of which automotive and aviation is an important segment.

Higher accuracy of 5-axis machining

① Machining for deep cavity molds

When side wall processing, the tool length of the 3-axis machining center is larger than the depth of the side wall, increasing the length of the tool will significantly reduce the strength, if the tool length is higher than 3 times the diameter, let the tool phenomenon will be difficult to ensure the quality.

Five-axis machining center, on the other hand, can use the spindle or workpiece swing, so that the tool and the mold sidewall always present a vertical state, improve the quality of the workpiece and extend the life of the tool.

③ Machining flat surfaces of molds

When processing flatter surfaces, the three-axis machining center needs to increase the tool path with ball cutter fine milling, but the center rotation line speed of the ball cutter is almost zero, which will damage the tool to a greater extent during the mold processing, and the service life will drop sharply and the surface quality will become poor.