In the process of machining parts of CNC machining of large parts, the precision of machined parts directly affects the quality of products. Some mechanical parts and compact equipment parts have very high requirements for machining accuracy. Improving the machining accuracy of CNC machining of large parts is the key to solve the problem. Through comparative research and analysis, the following countermeasures can be taken:

1、The Method of Improving Machining Accuracy by the Original Error of NC Machine Tools

In general, errors are unavoidable in the process of machining large parts on CNC machines. The error between the machined part and the cnc machined large part drawing data is inevitable. Generally speaking, this particular error is the original error.

2、Reasonably design the core parts of the machine tool to avoid large parts CNC machining errors

The positioning accuracy of machine tools has a great impact on the processing of parts, and is the core component that affects the positioning accuracy of machine tools. Such as straightness and levelness of feeding system, guide rail and working platform.

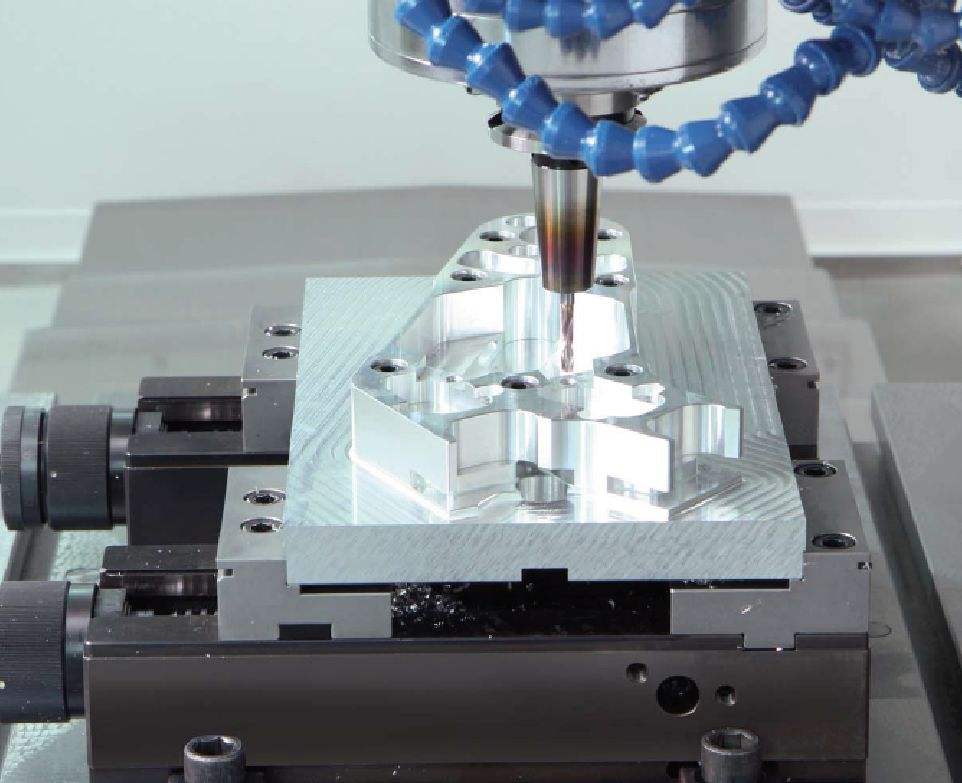

3、Adopt real-time monitoring technology to improve machining accuracy

What does CNC machining center do? It directly represents computer digital control. This is a processing technology widely used in the manufacturing industry. It can also be said that this is the symbol of the current manufacturing industry. CNC Machining centers are mainly used to simplify operations. Without system, it is almost impossible to finish multi axis machining at the same time with ordinary machine tools, such as surface machining.

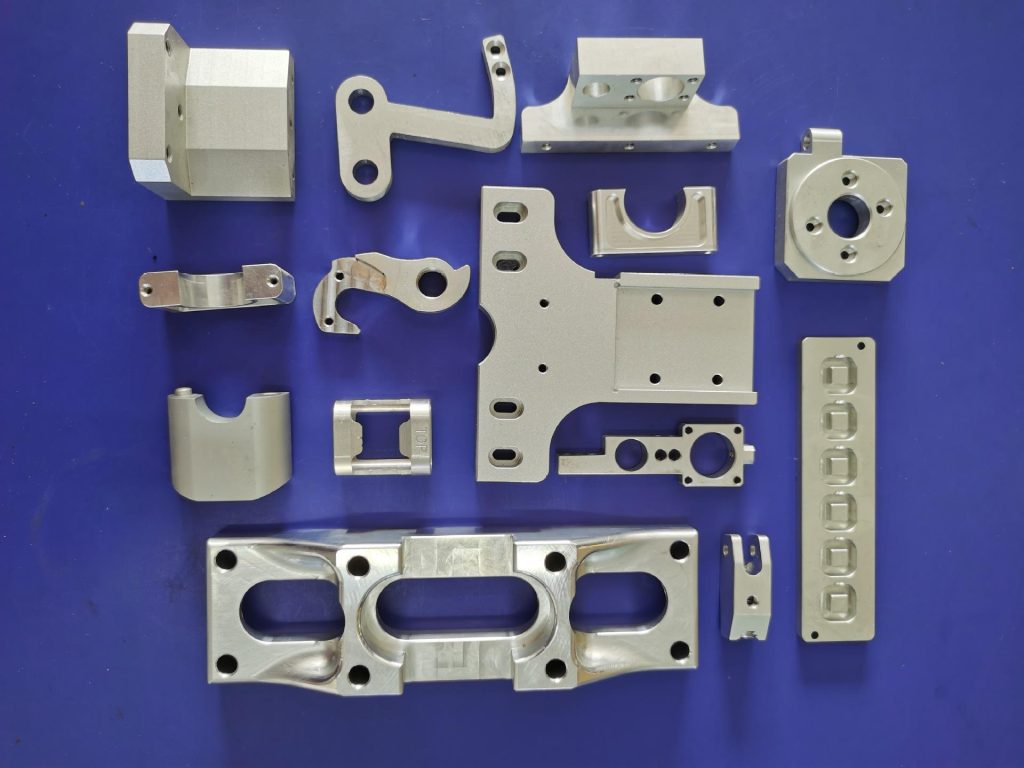

CNC machining centers mainly produce some precision parts, which are mainly used in automobile and motorcycle accessories, lighting, automatic robots, mechanical hardware, aerospace and military industry, electronic equipment, medical equipment, 3C digital, household appliances, communication mobile phones and other industries.

The processing materials of the centers are generally ABS, PC, PE, POM, PP, acrylic acid (PMMA), nylon, bakelite, silicone rubber, aluminum alloy, zinc alloy, magnesium alloy, titanium alloy, steel, copper, stainless steel, tantalum materials such as gold.