Items processed and manufactured by CNC include various surgical instruments used in medical operations, such as trocar (skin piercing device), bone drill and saw. When CNC is used to precision machined parts for medial devices, the parts are usually milled with 3-5 axes or turned with a movable tool CNC lathe. The most common types of machines used in the manufacturing of precision machined parts for medial devices, include CNC milling machine, lathe processing, drilling machine processing and computerized milling machine.

Reliability and high quality are the top priorities of medical parts processing. Therefore, the medical device industry has put forward new requirements for precision machining parts of professional medical devices. Difficult to machine materials, complex workpiece shapes and frequent CNC small batch production have put forward high requirements for cutters used to process professional medical devices. It is mainly shown in:

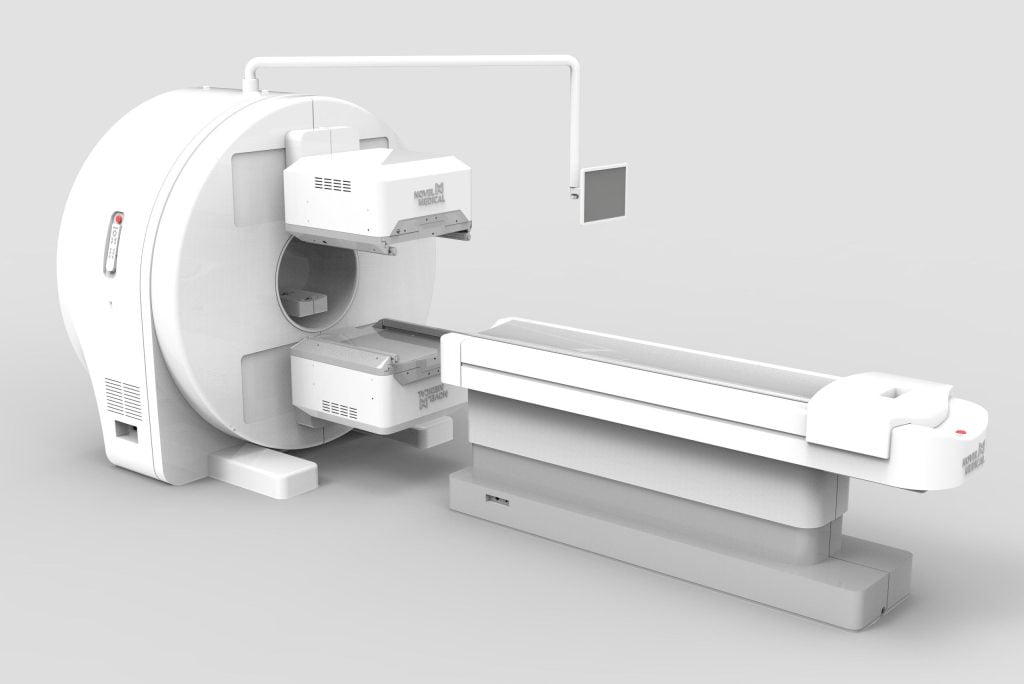

The requirements for CNC machine tools are relatively high

Advanced medical equipment processing equipment such as Swiss automatic lathes, multi spindle machine tools and rotary workbenches are completely different from commonly seen machining centers and lathes. They are very small in size and compact in structure; To meet this requirement, the structure of the tool also needs special design. The size of the tool should be very small, and the rigidity of the tool should also be guaranteed.

High requirements for cnc machining efficiency

For medical devices, the most important thing is the processing efficiency, that is, the processing rhythm. It is required to replace the blade in the shortest time.

From the workpiece itself

It is very different from other mechanical parts.Medical devices implanted into the human body are required to have a very good surface finish, high accuracy and no deviation. This requires that the design of the knife blade structure and the design of the blade coating meet high processing requirements.

CNC processing requirements:

Tolerances within the micrometer range are common in the medical industry, and selecting the right tool requires keen insight and rich experience. On the one hand, even drilling small holes requires the use of lubricants to reduce friction, reliably dissipate heat and handle fine iron chips at the blade; On the other hand, when producing cutting-edge medical devices (without burrs), it is necessary to use sharp and stable cutting tools to make the precision machined parts for medial devices more stable.