These characteristics make aluminum an ideal material for rapid prototyping and mass production with CNC machine tools. The machinability of aluminum parts processed by different grades of CNC machine tools depends on the efficiency of CNC machine tools and matching tools. Because of the high processing rate, the production team can offset the cost through a structured mass production strategy.

The maximum productivity of CNC aluminum parts can be achieved by optimizing the software for specific CNC machine tools, automatic tool indexing and the correct size of the CNC spindle. The simple way for the production team to improve the quality of China cnc machined aluminum parts is to select the right machining tools.

How to Select the NC Cutting Tools Suitable for China cnc machined aluminum parts

The blade is a removable cutting edge screwed on the cutting tool body, which is used to clamp on the tool holder of the CNC machine tool. The blade can be clamped to the tool with screws or a suitable adhesive. They are usually used for rapid prototyping and mass production of CNC aluminum parts. The blade is more suitable for machining aluminum parts with larger diameter, and can handle larger feed rate and deeper cutting.

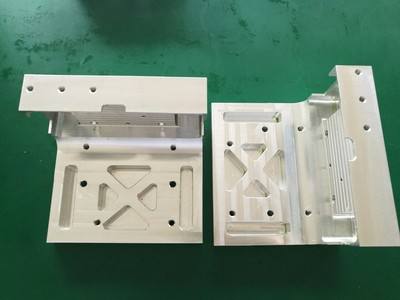

It is necessary to consider the specification of aluminum parts processed by China CNC machined aluminum parts

The ultimate goal of processing is to produce finished products that meet the design or specific requirements. Specifications can be part thickness, bearing capacity, and size. CNC machine tools can process aluminum parts of various sizes and shapes through effective tool sequencing and operation. Additional production requires the use of indexable tools. This type of tool allows the operator to replace the tool insert when necessary, thus allowing multiple automatic machining operations on aluminum parts processed by Chinese CNC.

CNC tool inserts have different cutting edges and can be used for post-processing operations, such as polishing and grinding of aluminum parts. In the NC aluminum processing environment, the performance of the blade depends on the shape, back angle and front angle of the blade.

Insert shape

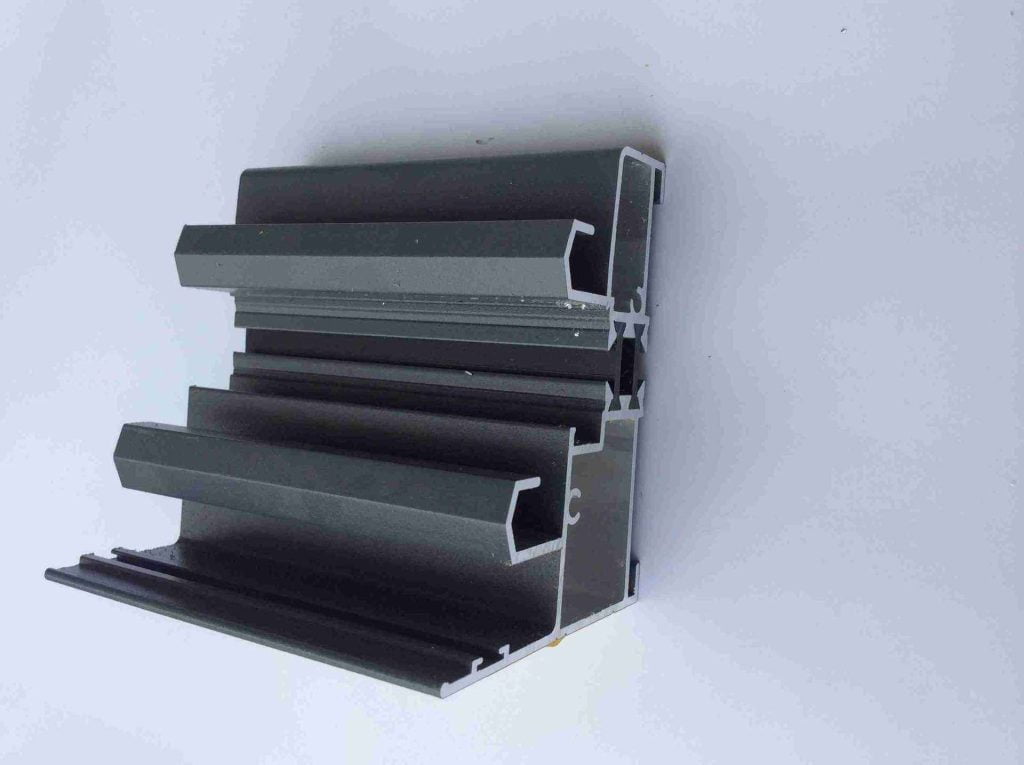

Tools for China CNC machined aluminum parts

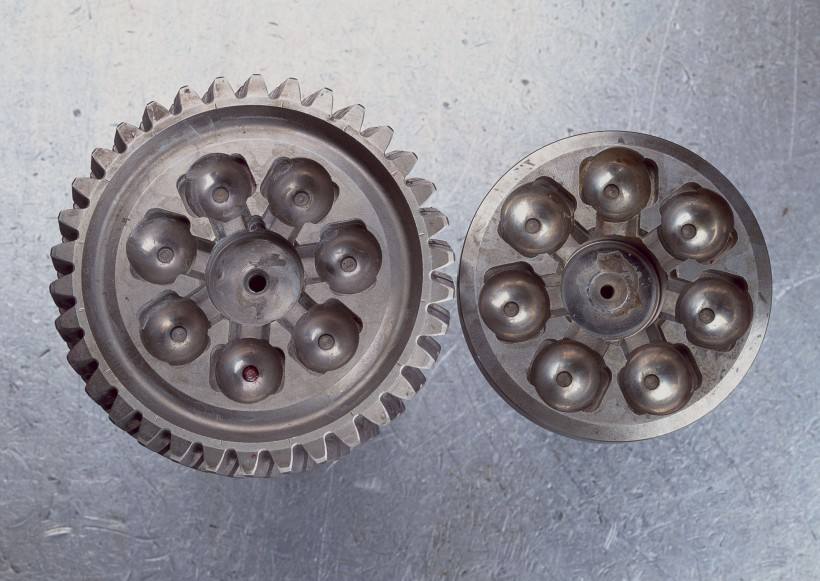

have specific geometric shapes that affect the quality of the final product. The blades have different shapes and are suitable for specific CNC tool handles. Aluminum alloy knives have diamond, round, triangle and square shapes. Better part quality can be obtained by using sharp blade. For example, 30 ° to 35 ° tool inserts are more suitable for high-speed surface machining of forged aluminum parts. High quality surface finish can be obtained by turning forged aluminum with diamond shaped inserts.

On the other hand, the CNC machining of cast aluminum parts will require operators to use round blades to obtain better quality. The cast aluminum surface is rougher; Machining with sharp tools will result in poor surface finish. The shape of the blade affects CNC parameters, such as feed rate, cutting depth, and tool clearance. Sharper shapes require smaller feed speeds and larger tool gaps.

Front angle and approach angle

The rake angle refers to the angle between the cutting tool tip and the workpiece clamped on the CNC machine tool. The angle can be positive or negative, depending on the position of the blade. When machining aluminum parts, it is recommended to use the front corner. As aluminum is a soft material, cutting resistance must be minimized throughout the production process.

When machining aluminum parts processed by CNC in China, chips will accumulate around the tool, which will also affect the quality of the final product. The positive angle will ensure effective chip removal. The positive rake angle helps to control the temperature by lowering the cutting temperature. This factor provides a sufficient processing environment for aluminum parts and improves the service life of the blade.

This paper mainly introduces the selection of China cnc machined aluminum parts. We can know that the specification, insertion shape, front angle and approach angle of aluminum parts should be paid attention to when NC machining aluminum parts. Aluminum is a kind of material with light weight and small density, and its processing is a challenging task. By selecting the correct tool, the goal of rapid machining can be achieved.