The more materials used in the part, the higher the cost. Similarly, the cost of special materials and very powerful materials is high. So how should we choose the processing materials for NC processing of China CNC machining plastic parts.

Aluminium

Aluminum is the most widely used material in China CNC machining plastic parts, and is an ideal choice for machinery and external parts. Compared with other metals, aluminum is usually processed faster than other metals, so it is the most economical method. Aluminum components can form a protective layer when exposed to the environment, thus improving strength and corrosion resistance.

Considering the characteristics of these high-quality materials, CNC milling aluminum is very suitable for the automotive, aerospace, healthcare and consumer electronics industries. Specific applications include aircraft accessories, electronic enclosures, medical devices, gears, and shafts.

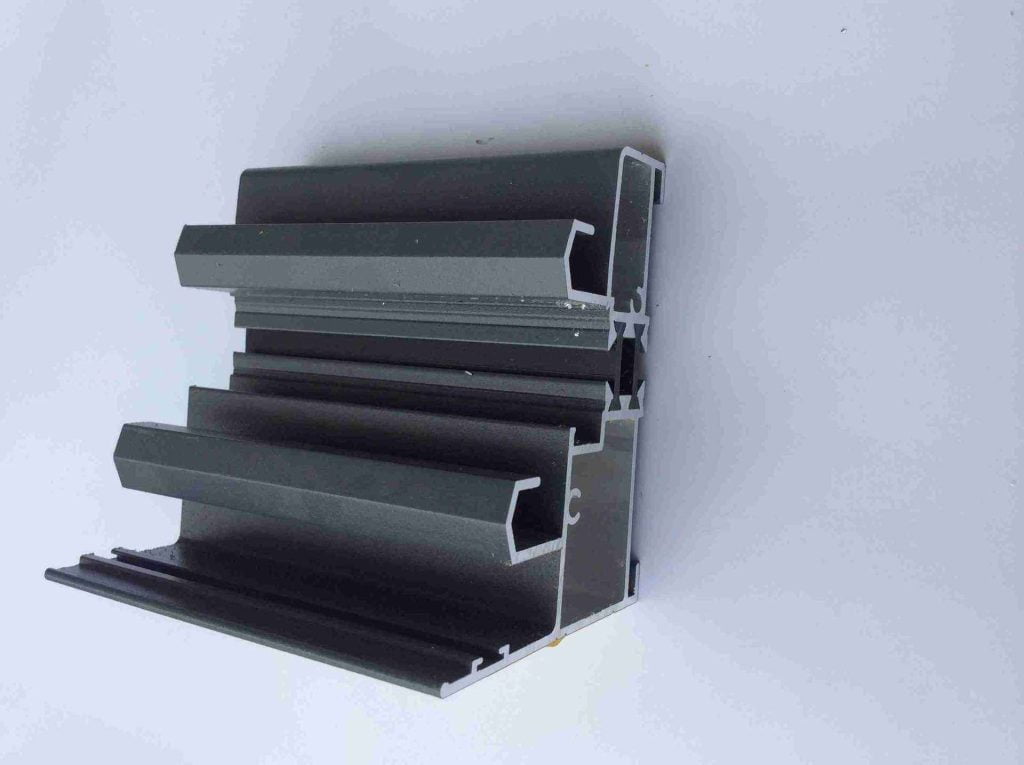

Aluminum cutting parts Aluminum

NC processing of China CNC machining plastic parts is the most commonly used universal aluminum alloy, with good strength to weight ratio and excellent machinability. It is the most common aluminum brand, usually used for auto parts, bicycle frames, sports equipment, RC frames, etc.

The main alloying elements are magnesium, silicon and iron. Like other aluminum alloys, it has high strength and weight ratio, and can naturally resist atmospheric corrosion. One of the disadvantages of 6061 is its low corrosion resistance when exposed to salt water and other chemicals. In more demanding applications, it is not as powerful as other aluminum alloys.

Titanium

Titanium is famous for its high strength, light weight, toughness and corrosion resistance. Welding, passivation and anodizing can enhance protection and improve appearance. Titanium has low polishing effect and low conductivity, but good thermal conductivity. This is a difficult material to process, and only professional tools can be used.

This material is usually more expensive than other metals. The crust is rich, but difficult to refine. It is most commonly used in military, aerospace, industrial and biomedical applications.

Brass

Brass processing parts Brass is recognized as one of the simplest and most cost-effective materials for China CNC machining plastic parts. It is a copper and zinc alloy, stable but not strong enough. Typical applications include medical devices, consumer products, electrical hardware, and contacts. Brass has low friction coefficient and high corrosion resistance, so it is also used in engineering, pipeline, steam engineering and even instruments. Because of its soft materials and ease of processing, it is used for pipe fittings, interior decoration and musical instruments.

Excellent machinability and excellent conductivity are ideal for applications requiring low friction. It is also often used in architecture to produce a golden appearance and aesthetic appearance.

Brass C36000 is a material with high tensile strength and natural corrosion resistance. It is usually used in a large number of applications because it is one of the simplest materials.

Copper

For China's NC processing of plastic parts, few metals can provide copper conductivity. High corrosion resistance is helpful for rust prevention of materials, and thermal conductivity is helpful for forming process in China CNC machining plastic parts. Common applications in the automotive industry include cooling systems and heat exchangers, as well as various engineering applications such as valves and radiators. However, it is important to know that copper is weak to certain chemicals, such as acid, halogen sulfide and ammonia solution.

Plastic

In addition to metal materials, SANS's high-precision CNC processing services are also compatible with some plastics. The following are the most widely used plastics in CNC milling technology. Plastic processing parts.

Nylon

Nylon, also known as polyamide , is a thermoplastic. It has excellent mechanical properties, excellent impact resistance, high chemical resistance, abrasion resistance and medium flame retardancy, so it is usually used. This includes short-term products for insulators, bearings and injection molding. The disadvantage is that it is easy to absorb water and moisture.