With the rapid development of science and technology, the requirements for the quality of modern investment castings are getting higher and higher. How to ensure the quality of castings is a problem that investment casting industry has been studying. In the process of ensuring the quality of castings, in addition to formulating a reasonable and scientific manufacturing process, it is more important to strictly control the quality of silica sol coating to ensure the quality of castings. Through strict control of coating parameters, coating quality and drying quality, the quality of precision castings can be further improved to ensure that enterprises qualified products.

Related characteristics of silica sol

Silica sol is a translucent colloidal solution with milky white appearance, which is stable alkaline in most cases and acidic in a few cases. Silica sol has low viscosity, good dispersion performance, can fully enter the solid materials to be filled, and can ensure the smooth surface of solid materials. On the surface of silica sol particles, there are light silanol groups and adsorbed water, which can effectively improve the wettability of silica sol. In addition, the silica sol also has good cohesiveness and reactivity. Drying and sintering after using the silica sol can form a solid film, and this film will not be dissolved in water and other substances once it is formed. Silica sol can effectively improve the mechanical and chemical properties of the mixed materials after homogenous mixing with organic resin. At the same time, the silica sol also has good stability. Once solidified, it will not be dissolved in water and will not deteriorate.

Silica sol coating and its preparation.

In the process of precision casting, the preparation of silica sol coating needs to select the appropriate preparation method according to the actual situation. The silica sol coating can be divided into surface coating and back coating when manufacturing the mold shell. The surface coating will directly contact with the liquid metal, which is also an important factor determining the surface quality of castings. It is required that this coating has good heat resistance, viscosity and lubrication.

The coating mainly consists of refractory, wetting agent, binder and defoamer. The back coating does not need to directly contact with the liquid metal. It is mainly used to ensure the strength, rigidity and other comprehensive mechanical properties of the shell. The composition of this coating is basically the same as that of the surface coating, but the viscosity of the binder is smaller, which can avoid the accumulation of coatings.

In addition, there is a transition layer coating between the surface layer coating and the back layer coating, which is mainly used to make the surface layer and the back layer well bonded together, thus ensuring the coating quality of the transition layer coating and the quality of the entire shell. The composition of this coating is basically the same as that of the above two coatings, except that the adhesive is more viscous, so that the surface layer and the back layer can be closely bonded.

During the preparation of silica sol coating, a certain amount of silica sol is added to the batching tank, and then a certain proportion of lubricant is added and stirred. During the stirring process, refractory powder is required, and then defoamer is added. In order to ensure the quality of coatings, it is necessary to control the proportion of each raw material and the mixing time, and use special coating configuration equipment, so as to ensure the quality of coatings and lay a foundation for ensuring the quality of precision castings.

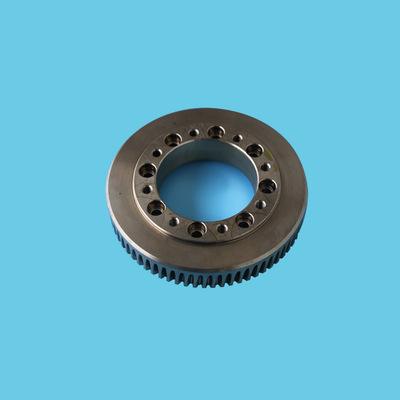

Silica sol precision casting is a product that requires very high dimensional accuracy. We can first choose profiles or cast carbon steel for processing. The advantage of using silica sol precision casting steel mold is that the material is cheap, while the disadvantage is that the mold is relatively bulky, and has certain requirements for the machining tool. It is difficult for some manual operations. How to judge the high temperature strength and stability of silica sol investment casting?

The interlayer drying time of silica sol precision casting will be further shortened. Although there are some products at present, the interlayer drying time of this enhanced silica sol can be shortened to 1h. The shell making environment, especially the wind speed, will have strict requirements, and the interlayer drying time of castings with long and thin holes should be appropriately extended.

The surface quality of silica sol precision casting is good and the high temperature strength is high. The whole product has good thermal shock stability and high temperature deformation resistance. The product is a less cutting or no cutting casting process. Such products also have advanced casting technology in the casting industry.