The machining accuracy of mechanical parts mainly depends on multiple factors such as workpiece, cutting tool, machine tool and machining technology. The accuracy of plane milling can be ensured by the following measures.

Avoiding vibration

Consider the causes of milling vibration and take the following measures to control and avoid it Select a process system with sufficient rigidity, such as sufficient machine power, rigid fixtures, reasonable structural dimensions of the milling machine, reasonable clamping method, clamping force, etc.

Before milling, attention should be paid to the reasonable adjustment of the clearance of all parts of the machine tool and locking the unused feed direction during machining. Reasonable selection of cutting angle of the tool and milling parameters.

Selecting advanced milling cutters

Choose various advanced indexable milling cutters and integral milling cutters to improve chip evacuation and control undercutting and overcutting.

Before milling, measure the dimensional accuracy of the milling cutter, shape accuracy and tooth accuracy of the forming milling cutter, and double check the grinding quality after the milling.

Test the mounting accuracy after installation to ensure the rotational accuracy of the milling cutter after installation.

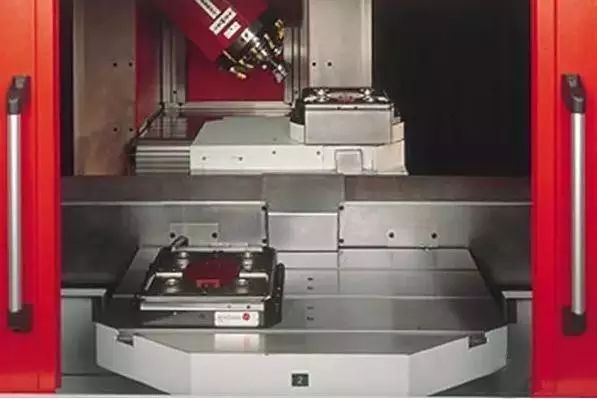

Select a fixture with corresponding accuracy

For the clamping of small, thin and easily deformed workpieces, set the clamping method in advance and reasonably select the clamping position, clamping force and the form of clamping device.

The slitting head or rotary table selected for workpieces with high slitting accuracy must be pre-tested for slitting accuracy, and optical slitting devices must be used if necessary.

Special fixtures should be used for batch processing, and milling allowances should be reserved for the first machining of the part to test fixture accuracy.

For the clamping of large workpieces, the clamping system should be designed in advance and the clamping position should be set to prevent deformation so as to keep the machining position in the correct machining position.

Selective refining method

Plane milling can use powerful step milling machine to improve machining efficiency and accuracy. If the method appearing in machining can be used, cutting should be done as much as possible.

The gear teeth of the milling sprocket can be machined with a vertical milling machine to improve machining accuracy. Cyclone and high-speed milling methods are used to improve the machining accuracy of spherical surfaces, splines, etc.

Flexible use of modification, combination and other methods of standard milling cutters to improve milling efficiency and dimensional and shape accuracy Use of optical and electrical measurement techniques to improve measurement and inspection accuracy, effective control of finishing allowances, and improvement of dimensional control accuracy of finishing operations