CNC precision parts processing is still involved in a wide range of fields. How can you say that? In fact, everyone can see it in daily life. The effect is remarkable, and it will be used more in some industrial equipment. Understand that the machining requirements of CNC precision parts processing are also high. Why, because customers are specifying the quality, and the advantages of such parts processing are great, it is necessary to ensure stronger and more trustworthy customers. This is CNC precision. Parts processing needs to be guaranteed.

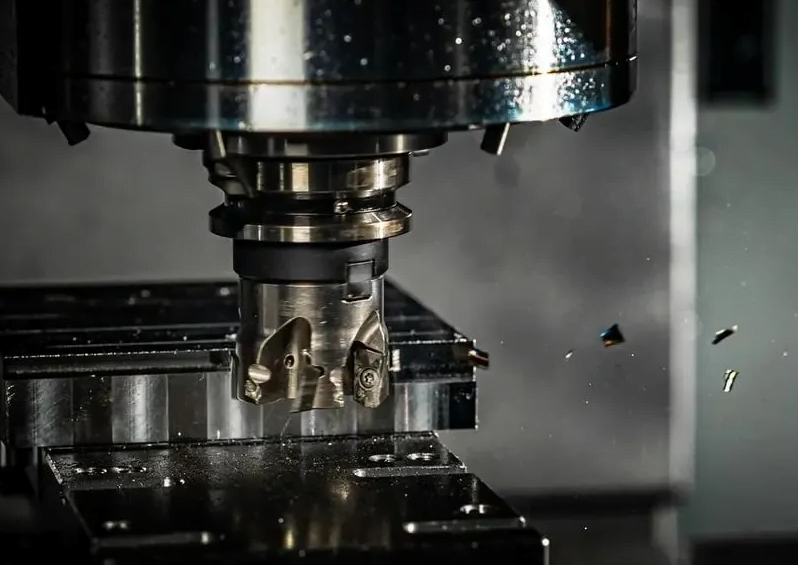

CNC precision parts processing

1. The cutting surface of CNC machining center milling plan view parts

When milling plan-like parts, the side edge of an alloy milling cutter is generally used for drilling. In order to reduce the blade marks and ensure the surface quality of the parts, careful planning is required for the cutting-in and cutting-out procedures of the CNC blade.

When milling the outline of the outer surface, the cut-in and cut-out points of the turning tool should be cut into and out of the surface of the part along the extension line of the outline curve of the part, and should not immediately cut into the part in the reverse direction to prevent scratches on the surface of the production and processing, ensuring that Parts are generally lubricated.

When milling the closed inner surface, if the inner surface agrees with the extension, it should be cut in and out in the tangential direction. If the inner contour curve is different from the unexpected ductility, the CNC blade can only cut in and out along the reverse direction of the inner contour curve, and set its in-cut and out-cut points at the intersection of two elements of the part contour. When some internal elements intersect without intersecting points, in order to prevent a notch at the general corner when the tool compensation is canceled, the cut-in and cut-out point of the CNC blade should be avoided in the corner.

It is displayed as the infeed road surface when milling an outer full circle with arc tool radius compensation. When the production and processing of the whole circle is completed, do not feed the knife at the tangent point, but let the CNC blade strengthen a distance along the tangential direction to prevent the CNC blade of the machining center from colliding with the surface of the product workpiece when the knife damage stop is canceled, and the product workpiece is abolished. . When milling the inner arc, the rule of cutting in from the radial direction should also be followed. A better way is to connect the mechanism from the arc to the arc-shaped production and processing road, so that the machining accuracy and production and processing quality of CNC precision parts on the surface of the internal thread can be developed.