Table of Contents:

- Introduction

- CNC Drilling Services: Techniques and Tools

- Best Practices for CNC Drilling Services

- Advantages of CNC Drilling Services

- Applications of CNC Drilling Services

- Challenges in CNC Drilling Services

- Future of CNC drilling services

- Conclusion

-

1.Introduction

CNC drilling services involve the use of computer-controlled machines to precisely and accurately drill holes in various materials. These drilling services have become increasingly important in the manufacture of complex parts and components used in various industries, including aerospace, automotive, medical devices, and electronics.

CNC drilling services have several benefits, including increased precision, lower labor costs, and higher efficiency. By optimizing drilling parameters such as speed, feed, and coolant, these services can produce high-quality parts with tight tolerances and complex geometries, making them an essential element in the manufacturing process.

In this article, we will discuss the techniques, best practices, advantages, and challenges of CNC drilling services, as well as their industrial applications and future developments.

-

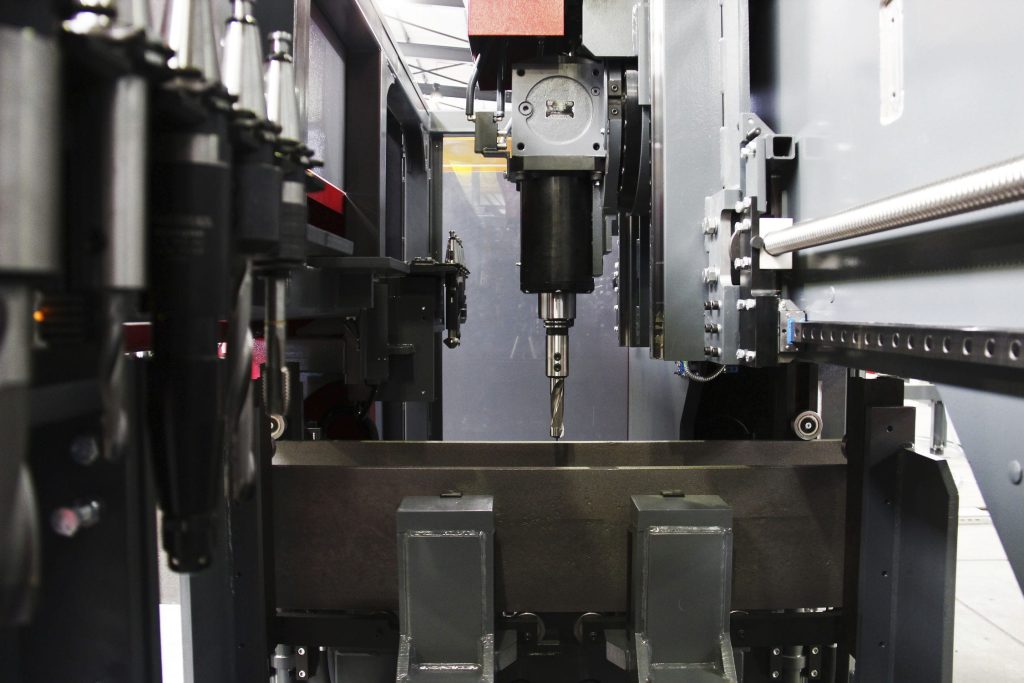

2.CNC Drilling Services: Techniques and Tools

CNC drilling services offer several drilling techniques, each with unique benefits and challenges. These techniques include:

1.Twist Drilling: Twist drilling is a basic and commonly used drilling technique in which the drill bit spins rapidly to create holes in the material. Twist drilling can be used on a variety of materials and can produce holes of different diameters.

2.Peck Drilling: Peck drilling is a technique that involves intermittently raising the drill bit out of the workpiece to eliminate chips and allow for deeper drilling. This technique reduces the risk of drill bit binding and breakage.

3.Gun Drilling: Gun drilling is a technique that involves using a long, single-fluted drill bit to produce precision holes. This technique is suitable for deep drilling applications, producing holes with high accuracy and surface finish.

The necessary tools for CNC drilling services include:

1.CNC Machines: These are machines that can perform drilling operations under the control of a computer program. CNC machines allow for high accuracy and repeatability in drilling operations.

2.Tooling: Tooling refers to the cutting tools used in drilling operations, including drill bits, countersinks, and center drills. The selection of appropriate tooling is critical for optimizing drilling parameters and achieving the desired results.

3.Workholding Devices: Workholding devices are used to hold the workpiece in place during drilling operations. These devices can include vises or clamps, chucks, or fixtures designed to accommodate specific workpiece shapes.

By understanding the different drilling techniques and selecting the appropriate tools for CNC drilling services, manufacturers can optimize the drilling process and produce high-quality parts and components with precision and efficiency.

-

3.Best Practices for CNC Drilling Services

To optimize CNC drilling services and achieve high-quality results with efficiency, manufacturers should follow best practices that are critical to ensuring the success of the drilling process. These practices include:

1.Selecting the Right Parameters: Selecting proper drilling parameters is critical to maximizing the effectiveness of CNC drilling services. Factors such as cutting speed, feed rate, spacing, and tool geometry should be considered and optimized for different materials and drilling applications.

2.Ensuring Proper Coolant Usage: A coolant is important in CNC drilling services to maintain the temperature of the cutting tool and workpiece, prevent the buildup of heat, and avoid damage to the drill bit. Manufacturers must use an appropriate coolant tailored to the material being drilled to ensure proper cooling and lubrication of the cutting surface.

3.Minimizing Drill Deflection: Deflection can occur when a drill bit is exposed to force or torque, which can cause the drill to veer off-course. To minimize deflection, increase drill rigidity by reducing tool overhang, selecting an appropriate drill point angle, and optimizing retract and entry angles.

4.Maintaining Proper Tooling: Proper maintenance of drill bits is crucial for extending tool life, reducing downtime, and improving accuracy, which can be achieved by regular inspection, cleaning, and sharpening of the cutting tools.

By following these best practices, manufacturers can optimize CNC drilling services, improve production and quality control, and produce quality parts and components efficiently.

-

4.Advantages of CNC Drilling Services

The use of CNC drilling services offers numerous advantages for manufacturers, making the process an essential element in the manufacturing industry. These advantages include:

1.High Precision with Repeatable Output: The use of CNC drilling services ensures high precision and accuracy in drilling operations. Computer-controlled drill bits can produce holes with tight tolerances, and the process can be repeated consistently with minimal errors.

2.Lower Labor Costs and Increased Efficiency: CNC drilling services reduce the need for manual labor by automating the drilling process, resulting in lower labor costs and improved efficiency. With the use of CNC machines, throughput and speed of production are increased, and the machines run continuously for long periods without stopping for changing the operator.

3.Flexibility in Production of Parts and Components: CNC drilling services offer flexibility in producing various parts and components of different shapes, sizes, and geometries. Automated drilling eliminates the need for manual adjustments, allowing for fast and efficient production runs.

In summary, the use of CNC drilling services provides manufacturers with improved precision, lower labor costs, reduced downtime between part production, and efficient production of complex parts and components. These advantages make CNC drilling essential in the manufacturing process and an attractive option for industries seeking precision, efficiency, and flexibility in drilling operations.

-

5.Applications of CNC Drilling Services

CNC drilling services have various industrial applications, playing a critical role in the manufacturing process of complex parts and components. Some of the industries that use CNC drilling services include:

- Aerospace: CNC drilling services are essential in the aerospace industry for drilling holes in aircraft parts, such as wing spars, leading edges, and bulkheads. The high degree of accuracy and repeatable output of CNC drilling services is crucial in meeting the industry’s tight tolerances and quality-control requirements.

- Automotive: CNC drilling services are used to produce a wide range of automotive components, including drivetrain and exhaust system components, fuel injection systems, and wheel bearings. CNC drilling services help automotive manufacturers produce parts with high precision and accuracy for optimal performance.

- Medical Devices: CNC drilling services are used in the medical device industry to produce components such as implants, surgical instruments, and diagnostic equipment. CNC drilling provides a high degree of precision, allowing for the production of components with exact geometries and tolerances.

- Electronics: CNC drilling services are used in the electronics industry to produce printed circuit boards, including drilling holes for electrical components, which ensure accuracy and avoid damage to the board’s circuits.

Examples of how CNC drilling enhances the manufacture of complex parts and components include:

- Production of turbine blades: CNC drilling is used to drill small cooling holes with precise tolerances in turbine blades for aircraft and power generation applications.

- Production of fuel injection components: CNC drilling is used to produce high-precision holes in fuel injection components for the automotive industry, allowing for optimal fuel flow and performance.

- Production of medical devices: CNC drilling is used to produce precise holes in medical implants, such as surgical screws and bone plates, accurate to sub-millimeter resolutions.

CNC drilling is widely used in manufacturing industries to produce some of the most critical parts for machines which have to function with precision and accuracy.

In summary, CNC drilling services play a vital role in various industrial applications, enhancing the production of complex parts and components with high precision, efficiency, and repeatability.

-

6.Challenges in CNC Drilling Services

While CNC drilling services offer numerous benefits, various challenges exist that need to be addressed to achieve optimal outcomes. Some of these challenges include:

- Surface deformation and Burr formation: During the drilling process, high force and pressure can cause surface deformation and burr formation. Surface deformation can cause inaccurate positioning of the part or component, while burr formation can lead to rough surfaces that may need further processing.

- Tool wear and Breakage: The continuous use of drill bits and other cutting tools in CNC drilling services can result in wear and tear, affecting the quality and accuracy of the drilling process. Tool breakage can cause damage to the workpiece, necessitating repair or replacement.

- Material drilling difficulties: Different materials have different properties, making some more challenging to drill than others. For example, materials such as titanium and Inconel are harder and require more cutting forces than softer materials like aluminum and copper.

To address these challenges, specific strategies are used to minimize their effects. For instance:

- The use of high-quality coatings on cutting tools to enhance their wear resistance and reduce the risk of tool breakage.

- The use of custom coolant systems that are tailored for specific materials, allowing for efficient heat removal during drilling.

- Optimization of drilling parameters, such as drill bit speed, feed rate, and tool geometry, to minimize surface deformation and burr formation.

By addressing these challenges, manufacturers can ensure efficient production of high-quality parts and components using CNC drilling services.

-

7.Future of CNC drilling services

As technology continues to evolve, the future of CNC drilling services is marked by emerging trends and future innovations. Some of these developments include:

- Advanced Automation: The future of CNC drilling services is automation. New strategies in machine learning and AI will increasingly automate the drilling process, reducing the need for manual labor.

- Integration with Industry 4.0 Technologies: CNC drilling services are becoming integrated with Industry 4.0 technologies such as the Internet of Things (IoT) to boost efficiency and productivity.

- Advancements in 3D Drilling: Advancements in 3D drilling technologies offer greater flexibility in the production of complex parts and components.

Innovations in CNC drilling tools:

- Diamond-coated drills: Diamond tools offer longer tool life and better cutting parameters than typical coated drills, while also providing improved overall performance.

- Ceramic drills: Ceramic drills are highly resistant to heat and wear, making them ideal for drilling hard materials such as Inconel.

- Smart drilling tools: Smart drilling tools can monitor the drilling process and adjust drilling parameters automatically, optimizing tool life and reducing errors.

V1 Machining:V1 Machining provides the best CNC drilling services for the fabrication of both small and large series of CNC drilling parts.

- 16 years experience in machining metal parts.

- Advanced equipment & professional testing,quality assurance.

- Digital management process,amazing efficiency.

In conclusion, the future of CNC drilling services is poised for advanced automation, integration with Industry 4.0 technologies, and advancements in 3D drilling. These future innovations, together with advancements in CNC drilling tools, will bring about game-changing quality, precision, and efficient drilling processes, ready to meet industry challenges of tomorrow.

-

8.Conclusion

CNC drilling services play a critical role in the manufacturing industry, offering high precision, efficiency, and flexibility in the production of complex parts and components. These services have several benefits, including reduced labor costs, improved accuracy and repeatability, and increased efficiency.

To ensure successful CNC drilling operations, manufacturers must adhere to best practices such as selecting optimal drilling parameters, proper coolant usage, minimizing drill deflection, and maintaining proper tooling. Challenges such as surface deformation, burr formation, tool wear, breakage, and material drilling difficulties also exist, necessitating specific strategies to mitigate their effects.

The future of CNC drilling services is marked by emerging trends in advanced automation, integration with Industry 4.0 technologies, and advancements in 3D drilling technologies. Innovations in CNC drilling tools, such as diamond-coated drills, ceramic drills, and smart drilling tools, are also set to revolutionize the industry.

In conclusion, CNC drilling services remain an essential element in the manufacturing industry, offering several benefits while also presenting challenges that require appropriate strategies and solutions. The future of CNC drilling services looks bright, with emerging trends and innovations set to bring about game-changing quality, precision, and efficiency in the drilling process.