Table of Contents:

- Introduction to Plastic CNC Machining

- Advantages of Plastic CNC Machining

- Types of Plastics Used in CNC Machining

- CNC Machining Processes for Plastic

- Factors to Consider in Plastic CNC Machining

- Applications of Plastic CNC Machining

- Limitations of Plastic CNC Machining

- Quality Control in Plastic CNC Machining

- Conclusion and Future of Plastic CNC Machining.

-

1.Introduction to Plastic CNC Machining

Plastic CNC machining is the process of cutting and shaping plastic material using computer numerical control (CNC) machines, which are programmed with precision tools and axes to create custom-designed parts and products. The process involves removing excess plastic material from the stock material and producing the final shape of the object according to the desired specifications.

Plastic CNC machining is widely used in various industries such as aerospace, medical, automotive, and consumer electronics due to its accuracy, consistency, and ability to produce complex geometries with tight tolerances. This process is commonly used for prototyping, low-volume production runs, and also for mass production where high quality and precision are required. It offers several advantages over traditional plastic manufacturing methods like injection molding, thermoforming, and blow molding, such as lower tooling costs, shorter lead times, and increased design flexibility.

-

2.Advantages of Plastic CNC Machining

There are several advantages of plastic CNC machining over other plastic manufacturing methods. Below are some of the most notable advantages:

- Precision: CNC machines are highly accurate and can produce parts with extremely tight tolerances. This level of precision makes it ideal for applications where accuracy is critical, such as aerospace or medical industries.

- Flexibility: Unlike traditional plastic manufacturing methods, CNC machining offers greater flexibility in design. The CNC machine can work with a variety of materials and can produce complex geometries with ease.

- Consistency: CNC machining offers a high degree of consistency from part to part. Once a part is programmed into the machine, it will produce identical parts every time.

- Low tooling costs: CNC machines do not require expensive molds or dies. This makes it an ideal choice for prototyping or small production runs.

- Short lead times: CNC machining has a relatively short lead time compared to other manufacturing methods. This means that parts can be produced quickly, reducing development time for new products.

- Scrap reduction: CNC machines produce minimal scrap material, unlike other manufacturing methods that may generate more waste. This can save money and resources in the long run.

Overall, the advantages of plastic CNC machining make it an ideal choice for industries that demand high-quality, accurate, and consistent plastic parts.

3.Types of Plastics Used in CNC Machining

Several types of plastics are available for use in CNC machining. The choice of plastic depends on the specific application and the properties required for the finished product. Below are some of the most common types of plastics used in CNC machining:

- Acetal (POM): Acetal is a thermoplastic with good stiffness, toughness, and dimensional stability. It is often used in the manufacture of precision gears, bearings, and other mechanical components.

- ABS: ABS (Acrylonitrile Butadiene Styrene) is a lightweight and durable plastic with good impact resistance. It is commonly used in the automotive and consumer electronics industries.

- Nylon: Nylon is a strong and flexible plastic with good wear resistance. It is often used in bearings, gears, and other mechanical parts.

- Polycarbonate (PC): Polycarbonate is a strong, clear plastic with good impact resistance. It is used in the production of high-strength windows, lenses, and other transparent parts.

- Polyethylene (PE): Polyethylene is a lightweight and flexible plastic with good chemical resistance. It is used in food packaging, medical devices, and other applications where cleanliness is important.

- Polypropylene (PP): Polypropylene is a lightweight and strong plastic with good chemical resistance. It is often used in packaging, automotive, and consumer electronic applications.

- PEEK: PEEK (Polyetheretherketone) is a high-performance plastic with excellent mechanical, thermal, and chemical properties. It is commonly used in aerospace, automotive, and medical applications where high strength and resistance to high temperatures are required.

These are just a few of the many types of plastics used in CNC machining. The choice of plastic depends on the specific requirements of the application such as strength, flexibility, chemical resistance, or other properties.

-

4.CNC Machining Processes for Plastic

There are several CNC machining processes used for plastic. The most common processes include:

- Milling: Milling is the process of cutting a flat or curved surface into a piece of plastic using a rotating cutting tool. The tool moves along multiple axes to produce the desired shape and can create complex geometries with high precision.

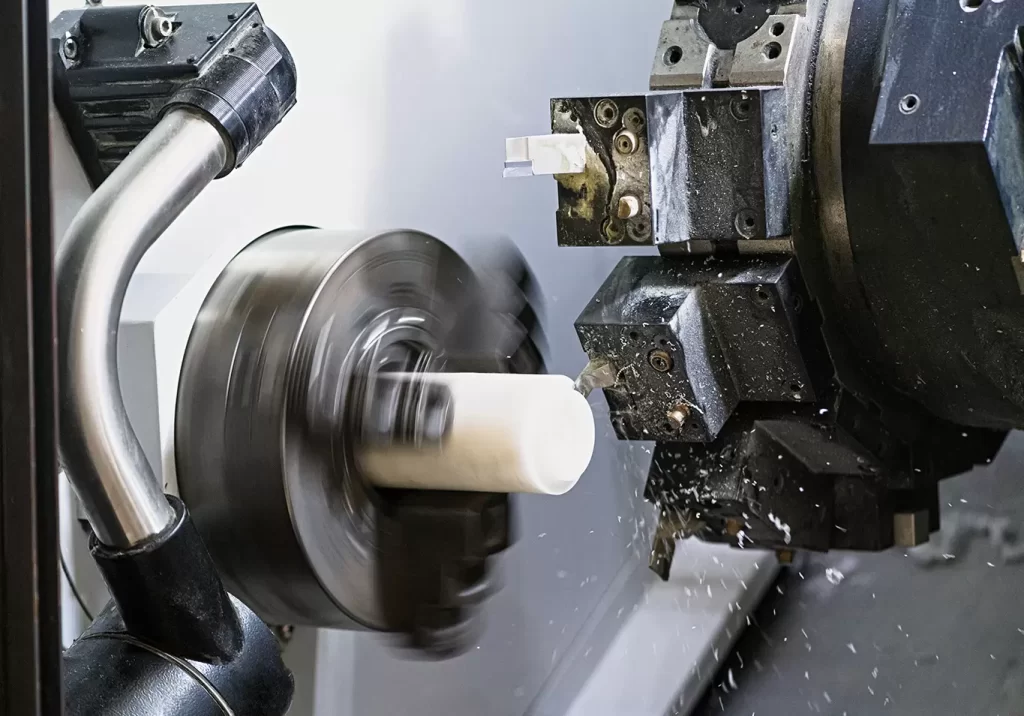

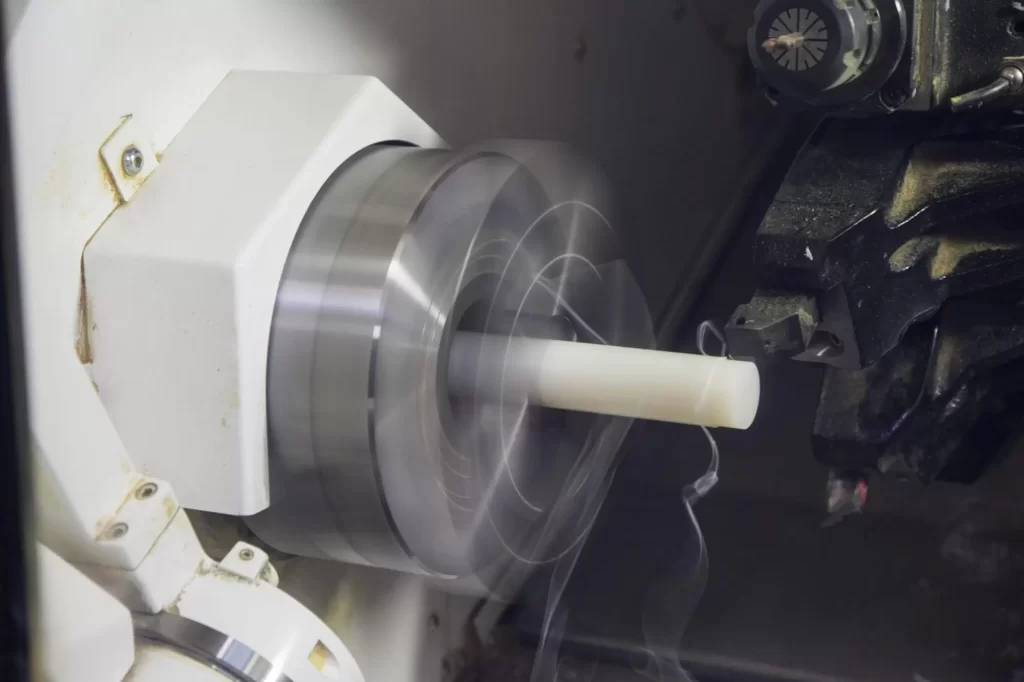

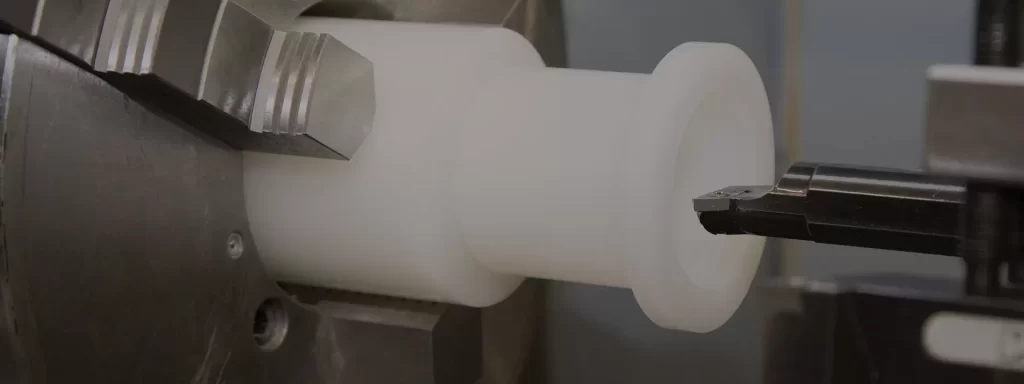

- Turning: Turning is the process of cutting a cylindrical or conical shape into a piece of plastic. The workpiece rotates on a spindle while a cutting tool moves along multiple axes to produce the desired shape.

- Drilling: Drilling is the process of creating holes in a piece of plastic with a rotating drill bit. It can produce holes of various sizes and shapes with high accuracy.

- Routing: Routing is a process similar to milling, used to cut complex shapes into plastic material. A rotating cutting tool follows a programmed path to produce the desired shape.

- Laser Cutting: Laser cutting uses a focused laser beam to cut through plastic material. It can create precise cuts in thin sheets of plastic and is often used for prototyping and small-scale production.

- Waterjet Cutting: Waterjet cutting uses a high-pressure stream of water mixed with an abrasive material to cut through plastic material. It can create accurate, intricate cuts in thick and hard materials.

- Thermoforming: Thermoforming is a process where plastic sheets are heated and then formed into the desired shape using a mold. CNC machining is often used to create the mold, allowing for precise and accurate shapes.

These are just a few of the many CNC machining processes used for plastic. The choice of process depends on the specific requirements of the application, such as the desired shape, size, and accuracy of the final product.

-

5.Factors to Consider in Plastic CNC Machining

When it comes to plastic CNC machining, there are several factors to consider to ensure successful and efficient production. Below are some of the key factors to consider:

a. Material Selection: The choice of plastic used in CNC machining depends on several factors such as the properties required for the finished product, the application, and the budget. Different types of plastics have different strengths, weaknesses, and properties. Factors to consider when selecting a plastic material include strength, flexibility, heat resistance, chemical resistance, and cost.

b. Tool Selection: The selection of cutting tools and related equipment is crucial in CNC machining. Factors to consider when selecting tools include material hardness, size, and complexity of the part, the desired surface finish, and the type of plastic being machined. Choosing the right tool can ensure efficient production, minimize waste, and reduce downtime.

c. Surface Finish: Surface finish refers to the quality and smoothness of the plastic surface after machining. A smooth surface finish can improve the appearance of the product, increase durability, and make it easier to clean. Surface finish is affected by factors such as tool selection, feed speed, and the type of plastic being machined.

d. Tolerance: Tolerance refers to the degree of accuracy in the dimensions of the finished product. CNC machines can produce parts with very tight tolerances, but this depends on factors such as the type of plastic material, tool selection, and the accuracy of the CNC machine.

e. Cost: The cost of CNC machining is affected by several variables such as material selection, tool selection, complexity of the part, and production volume. Choosing the right materials, tools, and production volume can help to minimize costs and maximize efficiency.

Overall, careful consideration of these factors is essential for successful plastic CNC machining. The right material, tool selection, surface finish, tolerance, and cost will ensure efficient and accurate production that meets the specific needs of the application.At the same time, you can choose the V1 Machining,they can Provide manufacturing process, metal, and plastic instructions to meet the specific requirements of your CNC machined parts.

-

6.Applications of Plastic CNC Machining

Plastic CNC machining has many practical applications in various industries due to its accuracy, consistency, and flexibility. Below are some of the industries that commonly use plastic CNC machining and their specific applications:

a. Aerospace: CNC machined plastics are commonly used in the aerospace industry for producing critical parts such as bearings, gears, and other components that require high strength, durability, and accuracy. Plastics are lighter than metals, making it ideal for aerospace applications where weight is a crucial factor.

b. Medical Industry: The medical industry uses CNC-machined plastics to produce various medical devices such as surgical tools, implants, and diagnostic equipment. CNC machined plastics can create precise and intricate parts that meet the exact specifications of the application with high accuracy and consistency.

c. Automotive Industry: The automotive industry uses CNC machined plastics to produce various parts like gears, bearings, and connectors. Plastics provide excellent resistance to heat, chemicals, and wear, making it the ideal material for engine compartments, fuel systems, and electrical systems.

d. Consumer Electronics: CNC-machined plastics are widely used in the production of consumer electronics, such as laptop cases, mobile phone components, and other electronic devices. Plastics offer excellent durability, resistance to shocks, and insulating properties, making it ideal for electronic applications.

Overall, CNC machined plastics have many practical applications in many industries because of their strength, durability, flexibility, and accuracy. CNC-machined plastic parts are widely used in industries where accuracy, complexity, and customization are critical such as aerospace, medical, automotive and consumer electronics.

-

7.Limitations of Plastic CNC Machining

While plastic CNC machining offers many advantages, there are also some limitations to the process. Below are some of the most notable limitations:

- Material limitations: Although there is a wide variety of plastic materials available for CNC machining, some materials are difficult to work with due to their chemical composition and properties. For example, some plastics produce toxic fumes when heated, requiring specialized equipment and handling.

- Size limitations: The size of the workpiece is another limitation of plastic CNC machining. The size of the CNC machine and its capabilities may limit the size of the workpiece that can be produced accurately.

- Complexity limitations: While CNC machining can produce complex geometries, there are still limits to the complexity of parts that can be produced. Extremely intricate parts may require multiple machining processes to achieve the desired shape and dimensions.

- Higher cost: CNC machining can be relatively expensive compared to other manufacturing methods, particularly for low-volume production runs. The cost of equipment and material setup can be a significant barrier for small businesses or startups.

- Surface finish limitations: Although CNC machining can produce a high-quality surface finish, some plastic materials are more difficult to machine than others, which can result in a rough or non-uniform surface. This may require additional post-processing steps such as sanding or polishing.

Overall, while plastic CNC machining offers many advantages, there are some limitations to this process, particularly around material and size constraints that make it less suitable for some applications. However, careful consideration of these limitations can help ensure that CNC machining produces high-quality parts that meet the specific needs of the application.

-

8.Quality Control in Plastic CNC Machining

Quality control is a critical aspect of plastic CNC machining to ensure accuracy, consistency, and reliability of the finished product. Below are some of the key quality control measures to consider:

- Inspection of materials: The first step in quality control is to inspect and verify the quality of the raw material being used in the machining process. By verifying material properties such as strength, composition, and density, any potential defects or variability in material quality can be identified early on.

- Calibration of equipment: CNC machines require regular calibration to ensure accuracy and consistency in the machining process. Calibration checks, including X-Y-Z axis measurement, spindle performance, tool tip, and RPM should be performed regularly.

- In-process inspection: During the machining process, it’s important to perform in-process inspection to ensure the parts are being produced accurately and within tolerances. Quality checks can be performed using a variety of equipment such as metrology probes, digital height gauges, and micrometers.

- Final inspection: After the parts have completed machining, the final inspection is performed to confirm they meet the specifications of the customer. Final inspection can include checks for dimensional accuracy, surface finish, and physical or mechanical properties.

- Documentation: It’s essential to have proper documentation throughout the quality control process. Detailed records of the raw materials used, machine settings, in-process inspection results, and final inspection reports should be maintained to allow for any issues to be easily traced and resolved.

By implementing strong quality control measures such as these, plastic CNC machining ensures that finished parts are compliant with industry standards and meet the requirements of the customer. This helps to avoid returns, rejections, warranty claims, and other costly issues while ensuring high-quality, accurate, and reliable parts.

-

9.Conclusion and Future of Plastic CNC Machining.

In conclusion, plastic CNC machining is a highly effective and precise process used to manufacture complex plastic parts. It provides a range of advantages, such as high accuracy, flexibility, efficiency, and customization, which make it ideal for various industries, including aerospace, automotive, medical, and consumer electronics.

With technological advancements, plastic CNC machining is continuously improving in terms of speed, precision, and efficiency. For instance, the use of more advanced CNC machines with built-in sensors and monitoring systems has resulted in better automated quality control, and tighter process controls.

In the future, we can expect to see further improvements in the use of technology in plastic CNC machining. Innovations such as robotics for materials handling, additive manufacturing integration, and machine-learning algorithms will likely become increasingly crucial in advancing the capabilities and efficiency of plastic CNC machining. There will also be a continued push for more sustainable manufacturing practices, particularly with the increased awareness of environmental issues, which would require the development of more eco-friendly materials and large-scale recycling initiatives.

In summary, while there are some limitations and challenges in the plastic CNC machining process, it remains a valuable and practical solution for manufacturing high-quality and complex plastic parts. With ongoing advancements, we can expect to see plastic CNC machining becoming even more efficient, accurate, and versatile in the future, meeting the ever-changing needs of various industries.