Machine building skills have developed rapidly in terms of increased accuracy and productivity, and in terms of increased productivity, increased automation is something that countries are striving to develop. In recent years, precision parts machining has rapidly evolved from CNC to CIMS and is already in use to some extent. From precision machining to ultra-precision machining, which is also the direction of development of the world's major developed countries.

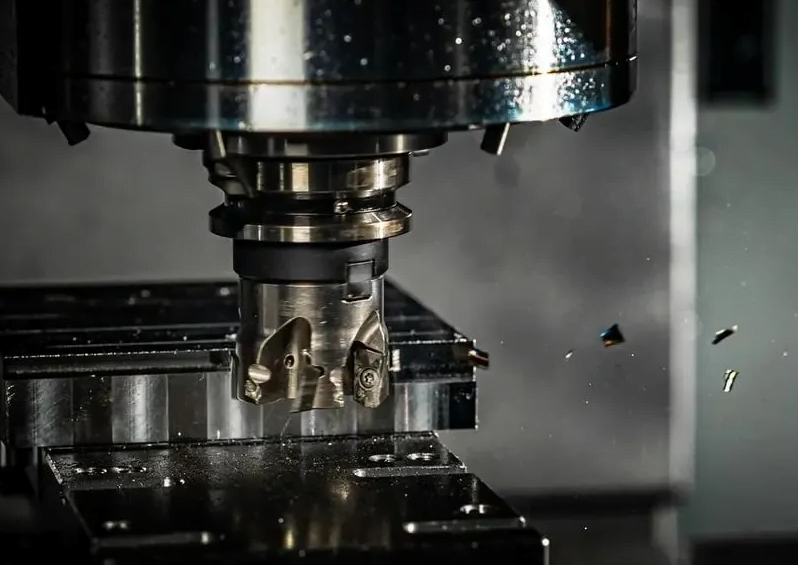

According to the mechanism and characteristics of processing methods, precision machining can be divided into four categories of tool cutting, abrasive machining, special machining and composite machining, with the development of processing technology, there are many new processing mechanisms, so in precision parts processing, especially in microfabrication, according to the parts forming mechanism and characteristics.

Divided into three categories of removal processing, combined processing and deformation processing, removal processing, also known as separation processing, is the use of force, heat, electricity, light and other processing methods to remove part of the material from the workpiece, such as cutting, grinding, electrical processing, etc.. Combined processing is the use of physical and chemical methods on the exterior of the workpiece attached to the accumulation, welding a layer of different materials, such as electroplating, vapor phase buildup, oxidation, carburization, bonding, welding, etc.; deformation processing is the use of force, heat, molecular movement and other means to deform the workpiece, change its scale, shape and function, such as casting, forging and pressing.

Visible processing concept has broken the traditional means of removal processing, with the characteristics of stacking, growth, deformation, etc., while emphasizing the appearance of the treatment, the formation of the appearance of processing skills.

Precision parts processing cutting processing and chipless process compared to the advantages of cutting processing is, first of all, both very high material removal rate, but also good economy, for example, compared with the laser plasma processing process is also the case. This is due to the fact that this process currently only supplies a large amount of energy in order to achieve high material removal rates and, on the other hand, there are still questions as to whether the workpiece can be machined to the required scale and shape accuracy.

Chipless pressure machining is mainly used for mass production, often requiring post-process cutting to obtain the final qualified workpiece shape, so the primary point of machining is to enable the workpiece to reach a high degree of accuracy, precision parts processing is widely used, especially with the development trend of small batch production, the shape and scale accuracy of the workpiece is increasingly demanding, opening up new and wider areas for precision parts processing.

The use of lathes naturally requires various turning processes, but it should also be noted that drilling, milling, grinding and gear cutting processes can all be concentrated on one lathe (process integration). This is now the development of the turning and milling centre of the composite machine tool processing approach.

Translated with www.DeepL.com/Translator (free version)