Every processing method has its own processing order. Our actual operators need to carry out processing according to its processing order, and cannot do it randomly, which will have a certain impact on the processed products, or It is a product quality problem, and the processing of precision mold parts is one of them. So what are the processing sequences? Let me tell you about it below.

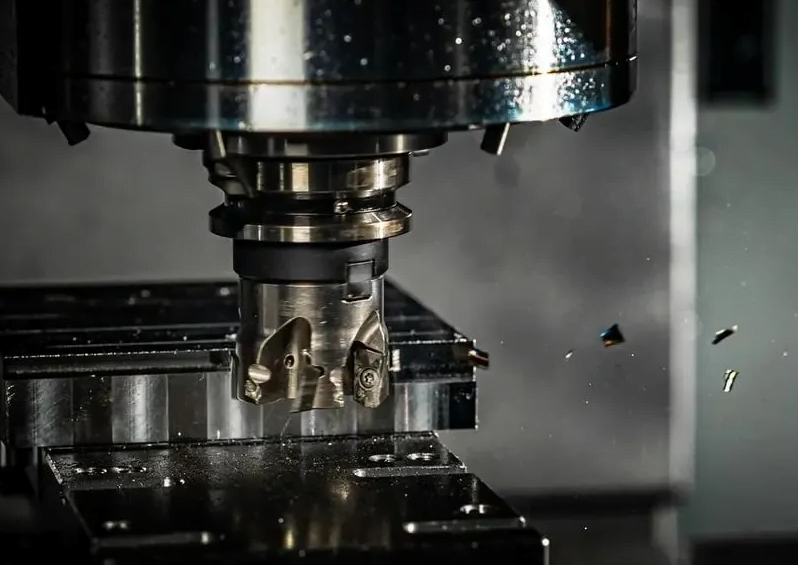

Precision mold parts

1. The layout of the processing theory should be considered according to the structure of the part, the condition of the rough embryo, and the requirements for positioning and clamping. The key is that the rigidity of the product workpiece is not damaged.

1. The processing of the previous process should not affect the positioning and clamping of the next process. Comprehensive consideration should be given to the processing process of the intermediate cross-type precision mold parts.

2. First terminate the inner wall processing process, and then terminate the appearance design processing process.

3. The process of processing with the same positioning, clamping method or the same tool should be terminated as far as possible to reduce the frequency of continuous positioning, the frequency of tool change and the frequency of moving pins.

4. For multiple processes terminated in the same equipment, the first process should be arranged with less damage to the rigidity of the product workpiece.

2. CNC blade centralized sorting method: it is to divide the process according to the common CNC blade, and use the same CNC blade to process any part that can be carried out on the part. Use the second knife, and the third to do whatever else they can. This can reduce the frequency of tool changes, shorten the engineering time, and reduce unnecessary positioning deviations.

3. The order of processing parts:

For parts with many processing contents, the processing part can be divided into several parts according to their structural characteristics, such as inner shape, appearance design, inclined plane or plane, etc. Generally, the plan and positioning surface are processed first, and then the holes are processed; the simple geometric design is processed first, and then the complicated geometric design is processed; the parts with lower precision are processed first, and then the parts with higher precision requirements are processed.

I will introduce the order of precision mold parts processing here. If you want to know more relevant information, please come to consult. We have more high-quality products for you to meet your requirements.