CNC machining centres, analysis of drawings, programming, work, edge finding, tool preparation, tool setting and running programs are all essential steps, one cannot be missing.

In the factory, there is always some batch work is often done, we can save the program to the computer, the next time you use it directly transferred into the machine. After the above steps, debugging the first piece of work and inspection after passing, do not follow this step again, directly on the job on the line. This time you need to do a positioning, so that you do not need a one to find the edge, improve efficiency, but also save a lot of time.

The following talk about the CNC machining centre common several positioning methods.

- Dead positioning.

The picture below shows how to position the pliers, find the edge, and then when working on the next one, just rely directly on the positioning. Some pliers have a threaded hole on the side, which can also be used for positioning.

- Tool bar positioning.

This is similar to the CNC turning tool positioning. This is a positioning program that needs to be programmed. As shown below, I used a Φ10 point drill for positioning, and the procedure is as follows

M6 T1

G0 G90 G54 X-5. Y0.

G43 H1 Z50.

Z0.

G1 Z-10 F800.

M00

G1 X-10 F1000.

Z0.

G0 Z100.

M01

However, note that this program is not possible on some machines because there is G1 and no speed, so the machine will think there is a problem with the program.

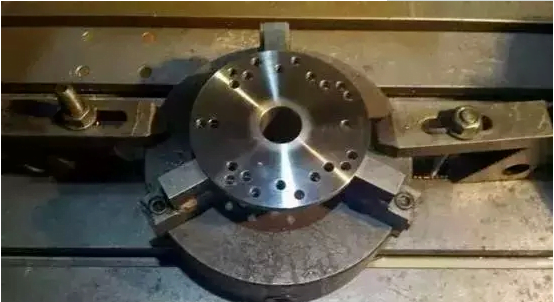

- Special fixture positioning.

General round work with a three-jaw chuck positioning, clip on also do not need a one to find the edge. There are also some work, need to do special fixture, the above have special pin positioning.

- Draw a line to position.

As shown below, milling a through slot, you can draw a line directly on the clamp, and put it in the approximate position every time you work on it. There are also some blank materials, shape than the size of the drawing, you can also draw a line to position.

These are commonly used positioning and are what we should be skilled at. Dry CNC machining centres, especially for products, encounter a wide variety of situations and consider the problem with flexibility and variety. Know the common methods, but do not stick to them.