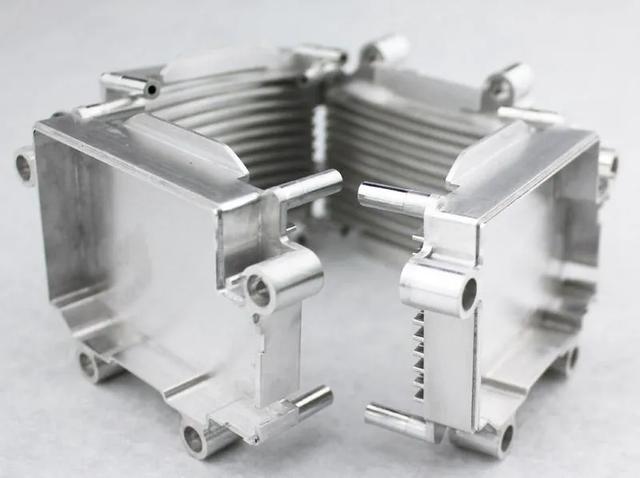

Precision parts processing, hardware processing accounted for a large part. To share with you what are the process properties of hardware, I hope it will help you!

01

Casting properties: refers to the suitability of the metal or alloy for casting some process properties, mainly including flow properties, the ability to fill the mould; shrinkage, the ability of the casting to shrink in volume when solidifying; deviation refers to the chemical composition unevenness.

02

Weldability: The property of a metal material to be welded together by heating or by means of heating and pressure welding, with the interface meeting the purpose of use.

03

Top gas section performance: refers to the performance of the metal material that can be granted top forging without breaking.

04

Cold bending performance: refers to the metal material at room temperature can withstand bending and not break performance. The degree of bending is generally used to bend the angle α (outer angle) or bend the diameter of the core d on the material thickness a ratio, a the greater or d / a smaller, the better the cold bending of the material.

05

Stamping properties: the ability of a metal material to withstand stamping and deformation without breaking. Stamping at room temperature is called cold stamping. The test is carried out by means of a cupping test.

06

Forging properties: the ability of a metallic material to withstand plastic deformation without rupture in forging and pressing processes.