Do you really understand five-axis machining?

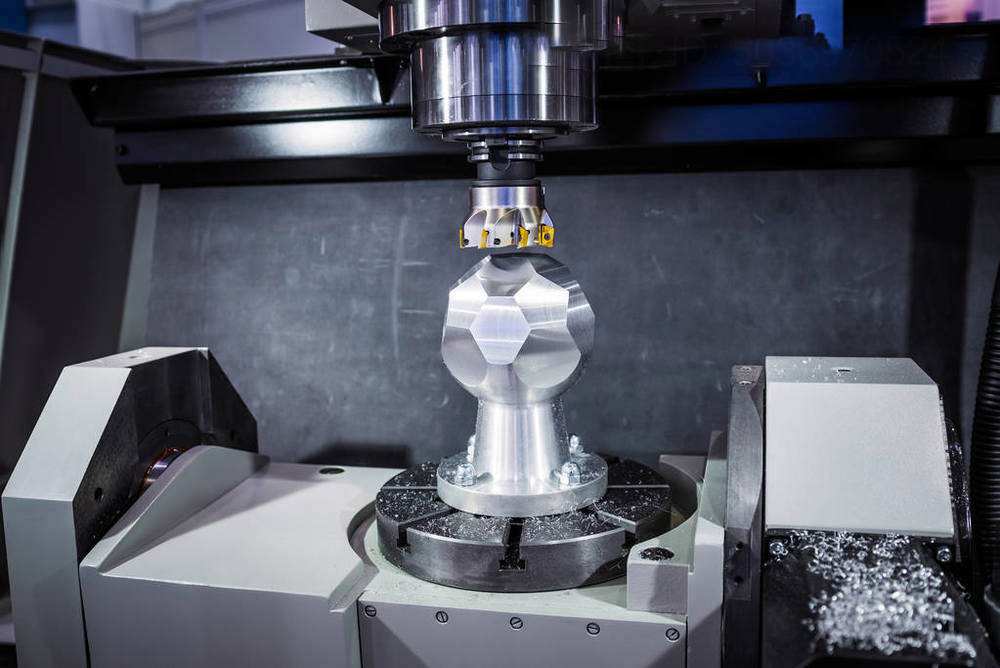

Five-axis machining, as the name implies, is a mode of CNC machine tool machining. Using linear interpolation motion of any five coordinates in X, Y, Z, A, B, C, the machine used for 5-axis machining is usually called a 5-axis machine or 5-axis machining center. But do you really understand five-axis machining? The development of […]

Do you really understand five-axis machining? Read More »