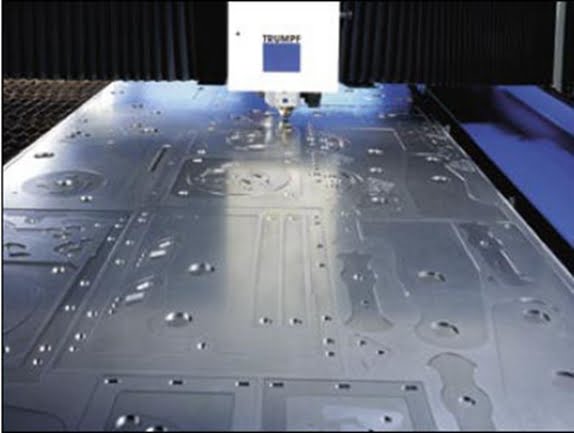

Today, the development of science and technology has made great strides in the production of equipment. Many materials are processed by CNC equipment in the material processing process and the demand for CNC sheet metal processing is gradually increasing.

In fact, this method of processing offers many advantages, such as achieving higher standards of precision during processing, avoiding errors during processing and better meeting customer requirements.

Secondly, CNC sheet metal processing is more in line with modern machining and production requirements. Traditional machining operations require a great deal of preliminary preparation. Stretching and drawing operations need to be carried out before finally going into production. This processing method allows for paperless production.

More attention is now being paid to this method of machining in order to make the process smoother, to avoid waste and to greatly improve production efficiency.

In order to guarantee the quality of the CNC sheet metal processing, it is necessary to do a good post inspection. The finished workpiece should be flat and free from burrs or machining marks, which will affect the quality of the product's appearance and the production requirements of the modern processing industry.

In addition, the thickness of the material should be uniform. During the machining process, employees must strictly follow the process and carefully check the finished product to meet the customer's production standards.

Today, there are a variety of process methods for CNC sheet metal processing, which can be completed with a wide range of raw materials. The processing method is therefore flexible and easy to use. In order to guarantee the quality of the processing, it is necessary to choose high-quality raw materials for the production, which is to improve the processing of the workpiece. This basis is also one of the issues that must be taken into account in sheet metal processing.