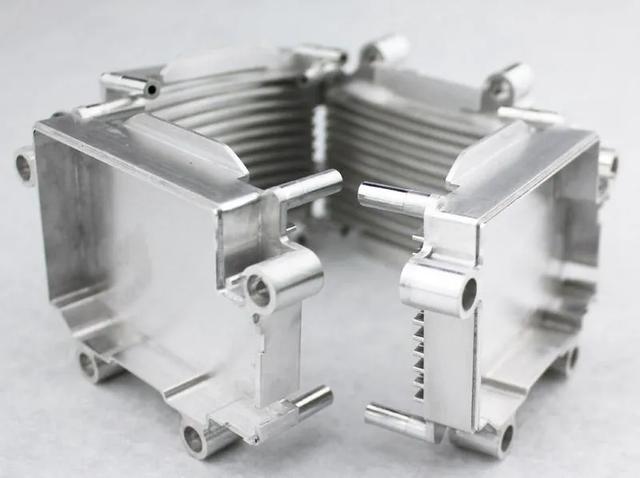

Precision machine parts processing itself is a very demanding processing means, its relative to the traditional processing method can achieve better results, there are many other processing methods do not have the advantages, precision machining is a rigorous and complex process, but it has been widely used in a variety of mechanical parts processing.

First of all, we are very clear that ordinary processing can not make high-precision products, because many parts in a certain extent exist defects. For example, some parts are non-standard products, only used in a specific range of trial, or these parts need to be assembled, so precision machinery zero machining will be used in these processes.

The sensitivity and accuracy of most mechanical manufacturing automation processes in the production system are very high, so manual operation will certainly be relatively weak.

The application of mechanical manufacturing automation technology in actual production can input specific program instructions for control, as far as possible to avoid mistakes caused by human factors, staff only need to control mechanical manufacturing automation can carry out various operations, greatly improve the quality of enterprise production.

It can be seen that the working capacity and production capacity of machinery manufacturing automation technology are relatively high, which can create more economic benefits for machinery manufacturing enterprises.

Is it dangerous?

No matter what type of enterprise in the process of manufacturing production, there will be some danger. In the case of the alarm function set in the mechanical manufacturing automation technology system, as long as the specific program is set, the work can be automatically suspended and automatically checked.

The application of machine manufacturing automation technology in the actual production process of enterprises can reduce the incidence of accidents to a minimum, which can greatly improve the safety of production.

Secondly, high-precision industry related work areas can also apply mechanical manufacturing automation technology, especially in the processing of chips and other electronic components has great advantages.

Mechanical manufacturing production with high safety performance, high quality, higher stability characteristics will create more social and economic benefits for enterprises.

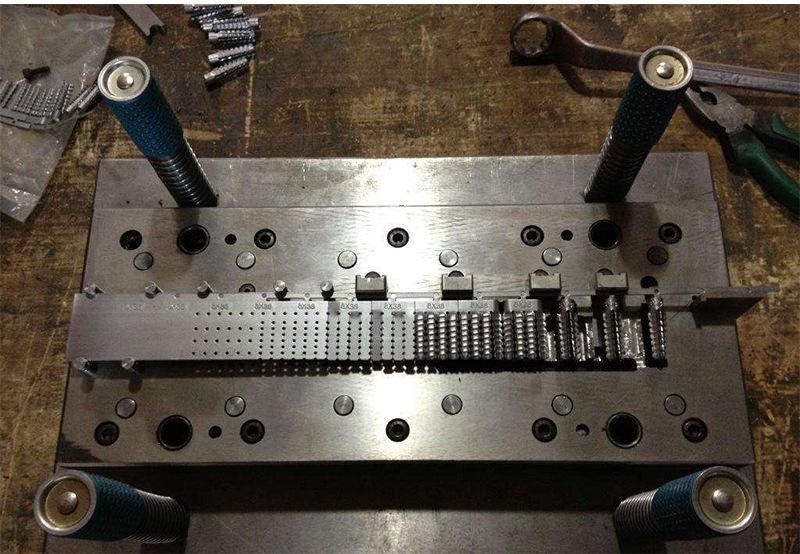

n addition to the usual machining, casting, forging, etc., there are many categories of machining. Casting classification also includes metal sand casting, melting mold casting, pressure excitation casting, centrifugal casting and other processing process to follow the correct technical standards and correct parameters to change the size of parts, size, position, shape represents the processing process.

What should we pay attention to when machining?

1, mechanical processing process to follow the machining manufacturing process, manufacturing process depends on the situation. The processing method is mainly the introduction of new products, technology and equipment.

- Mechanical equipment is mostly large equipment. The actual production should be considered when assembling mechanical equipment. In the process of each link to ensure its scientific rationality, so as to avoid improper use of equipment caused by production safety problems.

- If the mechanical processing technology is properly formulated, the production efficiency of machinery can be effectively improved, and the actual situation of processing technology and its own manufacturing can be improved.