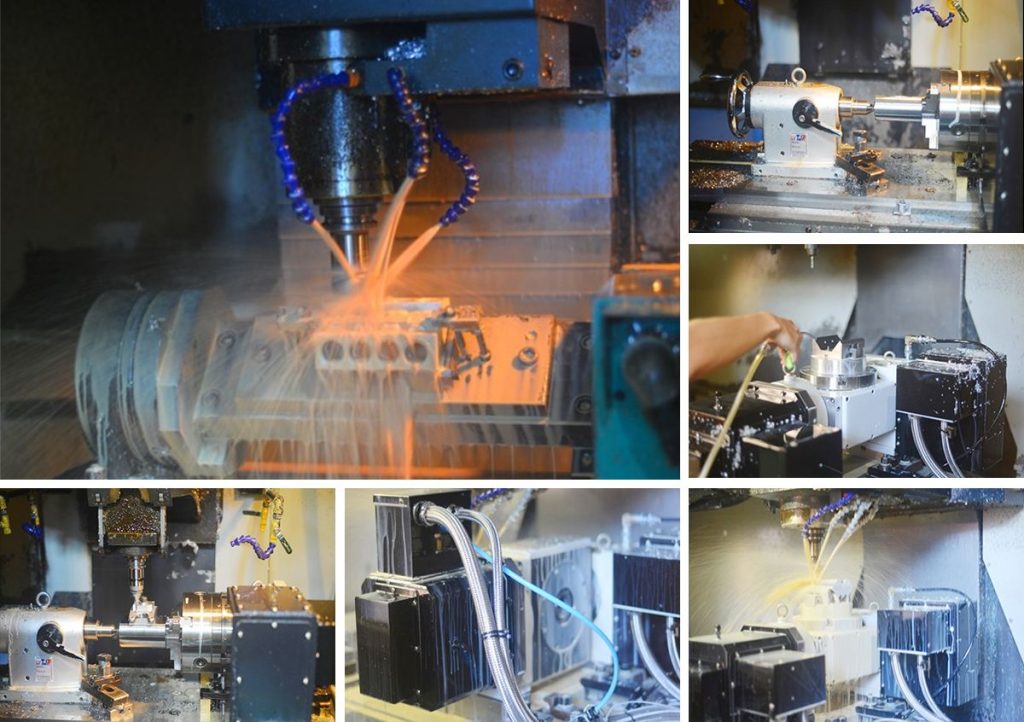

Three axis CNC machine tool machining centers are more common in the market, which have three linear offset axes of X-Y-Z. To put it bluntly, the four axis machining management center generally adds a rotation axis, which is generally called the fourth axis. The corresponding processing management center is the four axis processing management center.

Advantages of 4-axis machining

Machining process reduces clamping process and time

It can process complex surfaces that are difficult to process in the basic way, and even process some processing positions that cannot be observed

Centralized production and manufacturing

Reasonably improve processing efficiency and productivity.

What is a five axis CNC machine tool? How does five axis CNC machine tool develop?

Five axis machining part is just as the name implies.

The linear complementary motion of any five coordinates in x, y, z, a, b, c is adopted. The machine tool used for five axis machining part is usually called five axis machine tool or five axis machining center.

The CNC five axis linkage machining center has beautiful appearance, compact structure, high accuracy and high practicability.

The transmission components of the machine tool are all Taiwan originals. Based on the industry-leading LINUX control platform, the CNC system has reliable five axis linkage (RTCP) processing function and bevel processing function. After achieving one clamping (clamping at any position on the worktable), the five axis linkage machining of spatial complex surfaces, spatial multi surface milling, drilling Hinge and other processes.

Development of Five Axis Technology

For decades, it is generally believed that five axis NC machining technology is the only segment for machining continuous, smooth and complex surfaces.

When people meet unsolvable problems in designing and manufacturing complex surfaces, they require five axis machining part technology. However, five axis linkage CNC is the most difficult and widely used CNC technology. It integrates computer control, high-performance servo drive and precision machining technology and is applied to efficient, precise and automatic machining of complex surfaces.

In the world, the five axis machining part linkage numerical control technology is the symbol of the national production equipment automation technology level. Due to its special status, especially its important influence on aviation, space and military industries, and the complexity of technology, western industrial developed countries implement the export licensing system with five axis CNC system as strategic materials, embarrass China, and restrict the development of China's defense and military industries.

The last Toshiba machine tool incident released by the metal processing department was based on this blockade system! Compared with three-axis CNC machining, from the perspective of process and programming, five axis machining part for complex surfaces has the following advantages:

(1) Improve processing quality and efficiency.

(2) Expand the process scope.

(3) Meet the new direction of compound development