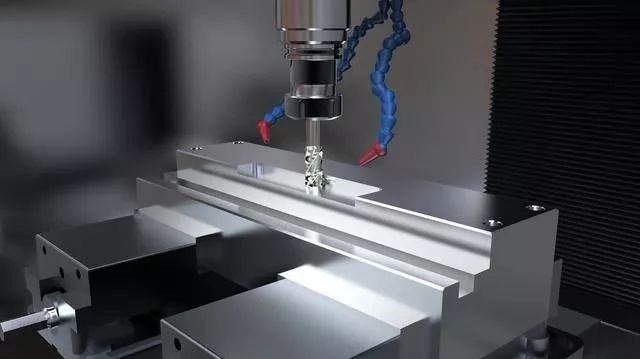

The CNC milling machines are structured in such a way that there are no tool magazines or tool changers, and the following differences exist between the two in terms of programming.

- T-code

As the CNC milling machine does not have a tool magazine, there is no need to use the T code to manage the tool magazine, which is managed by the operator. During programming the instruction :M00: allows the CNC to suspend operation, and when the operator has finished changing the tool, press the cycle start button and the CNC continues to run.

When the tool magazine capacity of the CNC machining centre is not enough, you can also command M00, by the operator to change the tool, at this time the CNC machining centre that is CNC boring and milling machine.

- M06 and M19 codes

M06 is the tool change command and M19 is the spindle orientation command. When there is a tool magazine, in order to carry out tool exchange, the instruction M06 is needed to make the tool on the tool magazine exchange its tool with the tool on the spindle. As the CNC milling machine does not have a tool magazine, it is also not possible to use the M06 instruction to make it exchange with the tool on the spindle, so there is no M06 instruction.

For tool change, the M19 instruction is required on the CNC machining centre in order to align the keyway on the toolholder with the end face key on the spindle end. As M19 is included in M06, it is not necessary to give a separate instruction. The M19 instruction is also not necessary here as the keyway on the toolholder is aligned with the spindle end key by the operator during tool change on the CNC milling machine.

There is also a difference between CNC milling machines and CNC machining centres in terms of tool change points. CNC machining centres have to change tools at a fixed point because they have a tool magazine. Generally located on the reference point, some on the 1st reference point, some on the 2nd,3rd or 4th reference point, depending on the machine structure. Use G28 or G30Pn to command the spindle to return to the reference point for tool exchange. The CNC milling machine, on the other hand, due to the operator changing the tool, is operated according to the workpiece in a convenient manual position for tool change, using the G00 command to return the spindle to the tool change point.

Whereas CNC machining centres, because they are fixed-point tool changes, must clear tool length compensation before tool changes in order to return the spindle to the reference point accurately, CNC milling machines are not as demanding. CNC machining centres can also cause accidents when clearing tool length compensation if the clearing position is not chosen correctly.

- G76 and G89 codes

G76 is the fine boring cycle, G89 is the back (reverse) boring cycle, because the CNC milling machine may not have M19 instruction, so it can not execute these two codes. However, in actual machining, the CNC milling machine can be used with the G88 instruction (manual retract) to achieve the function of G96. The operator manually moves the tool a distance in the opposite direction of the tool tip at the bottom of the hole, and then manually withdraws the tool from the bottom of the hole. After exiting, the tool is then moved back the distance it was moved in the direction of the tool tip, which has the same effect. As for back boring, the decomposition action of the programmable fixed cycle, with the cooperation of the operator, allows back boring to be carried out as usual.

CNC milling machines and CNC machining centres are identical in the programming of interpolation instructions, which are not described here.

From the above analysis, it can be seen that CNC milling machines and CNC machining centres are identical in their ability to perform boring processes. There is little need to divide CNC machining centre programming and CNC milling machine programming simply because of differences in T-codes and individual M-codes and fixed loop codes.

Comparison between CNC milling machine operation and CNC machining centre operation

The CNC system used for CNC milling machines is the same as the CNC system used for CNC machining centres and is therefore identical in terms of programming and operation. As the operator of a CNC machine, the main task is to set up the program data. That is, the workpiece co-ordinate system offset and the tool length offset are set up in the same way that the CNC milling machine and the CNC machining centre are set up. Other operations, such as program input and debugging is also the same, so the CNC milling machine operator can operate CNC machining centre: whether CNC milling machine or CNC machining centre, in the processing are according to the program go tool processing, in other words, CNC machining centre because it is automatic tool change, the operator is instead more relaxed, and there will be no tool change error.

If you divide the CNC milling machine programming and operation, CNC machining centre programming and operation, it is not necessary because the actual difference is too small. If the CNC milling machine operator is classified as a milling worker, the CNC machining centre operator is classified as a boring worker, the application of ordinary machine tools in the boring worker is higher than the milling worker, in the CNC machine tool is not appropriate:CNC machining centre due to the automatic tool change. Tool change time is short, no manual intervention, high degree of automation, short auxiliary time, and thus high productivity, accurate beat, not easy to make mistakes, mostly used in production lines. CNC milling machines, on the other hand, are less productive than CNC machining centres due to the manual tool change operation. However, due to the CNC milling machine without tool magazines and mold tool device, machine tool cost is low, still widely used.

Summary: from the above analysis concluded that the CNC milling machine and CNC machining centre are boring and milling composite function of the machine tool, its process capability is the same, the two in the programming, operation is also the same. CNC milling machine operators are fully capable of operating CNC machining centres.