Most of the workpieces with rotary surfaces can be machined by turning, such as internal and external cylindrical surfaces, internal and external conical surfaces, end faces, grooves, threads and rotary forming surfaces.

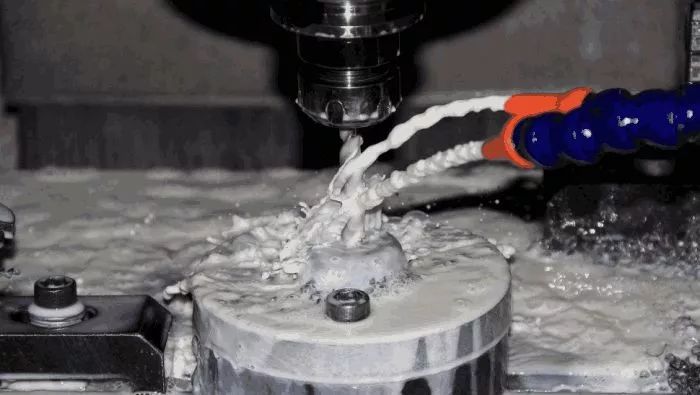

The tools used are mainly turning tools. The "milling process" is to fix the blank and use the high-speed rotating milling tool to cut the required shape and features on the blank.

"Turning"

is the use of the rotary motion of the workpiece and the linear or curvilinear motion of the tool on the lathe to change the shape and size of the blank to meet the requirements of the drawing.

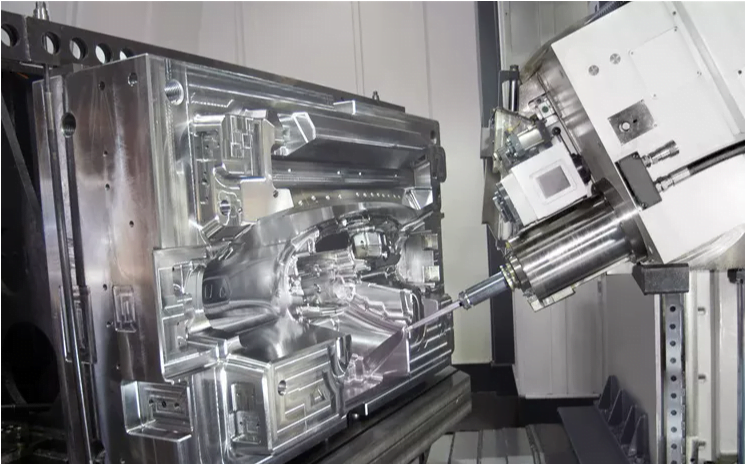

"Milling"

Is to fix the blank and use the high-speed rotating milling cutter to cut out the required shape and features on the blank.

Different characteristics

Turning refers to the lathe processing is part of the mechanical processing. Lathe processing is mainly used to turn the rotating workpiece with a turning tool.

Lathe is mainly used for processing shafts, discs, sets and other workpieces with rotary surfaces, and is the most widely used class of machine tool processing in machinery manufacturing and repair factories.

Different functions

Milling and boring machining center can carry out three-axis or multi-axis milling and boring processing, used for processing, molds, inspection tools, tire tools, thin-walled complex surfaces, artificial prosthesis, blades, etc. In the selection of CNC milling processing content, the advantages and key role of CNC milling machine should be fully utilized.